More Trimaran Folding Systems — Part 3

Hinge and Latch system (Gull-Wing)

This system works well on small trimarans and is employed on the Cross 18, Discovery 20/21 and the W17.

On the older Cross 18, this hinge system is created with vertical metal plates bolted to the sides of relatively  small beams, and mating plates are sandwiched together with a pivot bolt. Once unfolded, a lock bolt is added to keep it open. However, this arrangement means that the plates do project out above the beam. The fragile-looking beams survived as the ama volume was very moderate and the boats full beam was on the low side compared to current thinking.

small beams, and mating plates are sandwiched together with a pivot bolt. Once unfolded, a lock bolt is added to keep it open. However, this arrangement means that the plates do project out above the beam. The fragile-looking beams survived as the ama volume was very moderate and the boats full beam was on the low side compared to current thinking.

The Discovery 20 has large vertical reinforced plywood palms, the full height of its very deep beams, held in place with large bolts. Very strong, because the beams are large and deep. But as initially designed, the amas rose high in the air when folded, and as this created considerable windage on the highway, most Discovery owner/builders have since dispensed with the original hinging and they now remove the amas completely at the bolted joint. This permits them to be stowed much lower on a custom trailer and while this solves the windage issue, the craft should now more correctly be designated as a ‘demountable trimaran’, rather than folding (see photo).

The W17 has a somewhat neater system using horizontally flat upper hinges and lower latches, that allow the beams to be flat to walk on with nothing projecting much below the beam either. The wood beams are unique in that they are engineered with glass-reinforced palms on their ends, specifically to take and transmit the tension and compression loads, to and through the hinges and latches. On most W17's, these hinges and latches are now made of fiberglass which is not only lighter and corrosion proof, but also bonds very well to the engineered wood beam-ends, creating a strong continuous structure. See here for FG latches

engineered with glass-reinforced palms on their ends, specifically to take and transmit the tension and compression loads, to and through the hinges and latches. On most W17's, these hinges and latches are now made of fiberglass which is not only lighter and corrosion proof, but also bonds very well to the engineered wood beam-ends, creating a strong continuous structure. See here for FG latches

With a large, crafted fairing over the forward beam, this system has prove n particularly rugged as the first W17's have now sailed well over 3000 nmls over the last 10 years, including several 60 mile open water trips without an issue. Partly due to the curved shape of the W17 beams (that gives higher wave clearance) and the way they appear when being raised, many now call this the Gull Wing System ... with a nod to the Gull-Wing Mercedes 300SL of the 1950's. The photo at left shows the starboard ama folded while the port one is still extended.

n particularly rugged as the first W17's have now sailed well over 3000 nmls over the last 10 years, including several 60 mile open water trips without an issue. Partly due to the curved shape of the W17 beams (that gives higher wave clearance) and the way they appear when being raised, many now call this the Gull Wing System ... with a nod to the Gull-Wing Mercedes 300SL of the 1950's. The photo at left shows the starboard ama folded while the port one is still extended.

Added 2022. Due to greater ama weight on larger boats and the resulting difficulty to then lift them ‘up and over’, this system was initially limited to trimarans of 18ft or less, However, by building amas lighter (foam cored) and using a portable lifting derrick designed in 2022. the system can now be used for tris up to 20ft.

So, as long as 1) the ama lifting height is within practical range; 2) one has a wide enough place to open the amas before launching and 3), you either have a helper with you, or the above noted lifting derrick to lift the ama when alone, then this Gull Wing system will be tough to beat for boats under 16ft beam. It’s lightweight, inexpensive, strong, rigid, noiseless, fast to deploy, compact, good looking and creates no spray. What is not to like about that ?

New 2022: For boats under 20ft, the basic W17 system can also be used as a demountable if the hinges and latches are reversed*. This would allow the amas to drop-down about 30 deg. to a low support (or down 45 deg to the ground), on each side. Once both the upper and lower pins are pulled, the ama (with its fixed outer akas) can be brought in close to the main hull to sit on supports built out (or telescoping out) from the trailer, yet still not exceeding the original trailing width (7'-3 or 2.21m for the W17). With this arrangement, the mast could be left up and even used for lifting the amas up again to allow the latch bolts (now on top) to be slipped in place. As these hinge and latch bolts only work in shear. they do not need tools to hard-tighten them as just hand-tightened nyloc nuts serve very well. This adds yet another option to the use of this design that does not change the strength or sailing appearance of the boat in any way.

* 2023 NOTE to existing W17 owners. As the fore and aft beams have a slightly different depth, this reversal would theoretically require that the hinge alignment now be made on the UNDERSIDE of the beams instead of the upper side, so a Gull-Wing W17 cannot be fully converted to this 'demountable system only' without that change first being made. However, if prior to lowering, the lower pins were temporarily replaced with smaller ones of just 1/4" dia, this would create enough slack to offset the underbeam misalignment, allowing the ama to drop down to at least the height of the trailer bed, when all pins would be removed. This may prove to be a useful way to remove an ama for maintenance, with the main hull still on the trailer. (See more in Part 4 of these articles on Folding Systems)

5.

Telescoping Beams

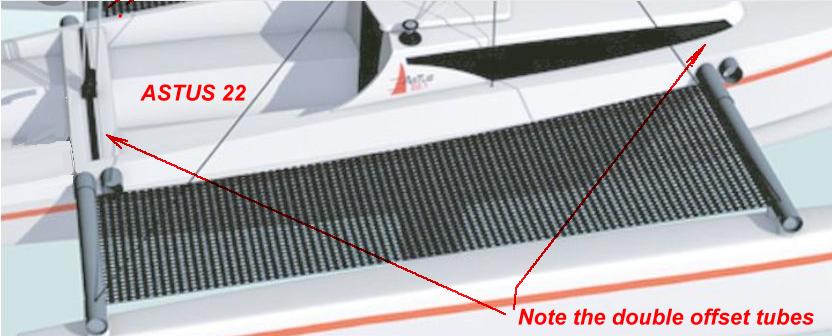

A few designs use telescoping beams, such as the French Astus, the L7 by Mike Leneman (no longer being offered). and some boats designed by Kurt Hughes and a few small kayak-based craft like the Windriders etc.

While theoretically quick and neat to use, common characteristics and issues are, .............

1) that unless the beams are very short, the two sides cannot be symmetric and identical. If one telescoping set must be behind the other, the beams are not in line Port and Starboard. This adds complexity to the building of both the main hull and amas, and arguably, creates a less attractive boat.

2) that the main. hull will always be encumbered with tubes or boxes that must pass through the main hull from one side to the other. Particularly if large, these not only take up much interior space but also break the structural continuity of the upper sides, often allowing cracks to develop after the craft have been in service a while.

2) that the main. hull will always be encumbered with tubes or boxes that must pass through the main hull from one side to the other. Particularly if large, these not only take up much interior space but also break the structural continuity of the upper sides, often allowing cracks to develop after the craft have been in service a while.

3) that many (and to different degrees) historically have a tendency to jamb in operation, as keeping them perfectly in line and free of sand, is a constant issue. Giving the tubes (or boxes) added clearance is sometimes the solution used, but then there can be constant movement while sailing, which, while generally acceptable technically, can be very annoying and disconcerting. Teflon sleeves can help.

4) that the overall expanded beam is geometrically limited by the arrangement, as each aka tube length cannot exceed the permissible road width without a complete dismantling.

For these reasons, this system is generally limited to relatively inexpensive small trimarans under 7m.

.

Finally, a WRAP-UP re cost, complexity and value (2022)

At the lower cost end, it’s hard to beat having no folding system at all, but with any trimaran over 8ft sailing beam, it has to be at least demountable. But there are at least two systems that can cost no more than a demountable one. These are the simple flat plate swing arm solution devised by Jim Brown and the up-and-over Gull Wing that I developed for the W17. Both can be set up to eliminate all annoying noise, with the raised height and greater physical depth of the Gull Wing making it more suitable for sea conditions requiring both strength and wave clearance. The swing arm is physically easier to fold by one person, whereas the Gull Wing takes less beam on a trailer (or in a garage) and if there are not 2 persons handy (when it’s an easy 2 minute task), a derrick can be made to fold each ama with only one person. See here.

The swing wing is a little quicker to fold, while the Gull Wing is stronger and far higher above waves, so your choice depends on what sort of boat you are needing and where you plan to sail. I’d estimate the extra cost for both these systems is roughly in the 2% range of the total cost range.

Other systems like the telescopic one could be 10-15% of the cost and have potential friction issues and offer less attractive appearance, while a more developed swing arm with folding nets etc, could be in the 10-20% range. The 'king of cost' has to be the original Farrier system that could be 20-25%. This is also so complex to set up to work correctly, that Ian finally sold it as modules, pre-assembled, that could be built into the hulls, but even 20 years ago, this was a $6000 kit. The other option is to work from plans and build it piece by piece. Ray Kendrick offers this for the Scarab, but it’s also expensive and time consuming to build and set up, and there is no guarantee it will work as smoothly as a factory Farrier. I once saw a photo of the nearly 100 parts for a Scarab folding system that is similar, and despite being assembled by a fine engineer who works on helicopters, it still did not work 100%.

The Farrier system is quite a masterpiece and when properly built and installed works great … but the downside is its cost, the amas fouling in the water and the spray these braced systems create as they can go fairly low to the waterlevel. Neither of the lowest cost systems have these issues, but not all have the strength to match the Farrier system for say ocean sailing plus the easy of in-water folding. Clearly, you need to match your boats operational needs with the most suitable system. I'd personally recommend adding fairings around the Farrier brackets to drive the wave tops down.

.

POSTSCRIPT (2019) for the Farrier System.

Having a good friend with a folding Farrier, I was encouraged to look at whether anything could be done to solve the main negative issue of the otherwise brilliant design … the issue of the side-turning ama when folded. This not only removes the relatively flat deck of the ama that is so useful and safer for docking and boarding on the Swing-Arm boats, but there's also the issue of side fouling when left afloat for long periods while folded – as in a marina (see Header photo above).

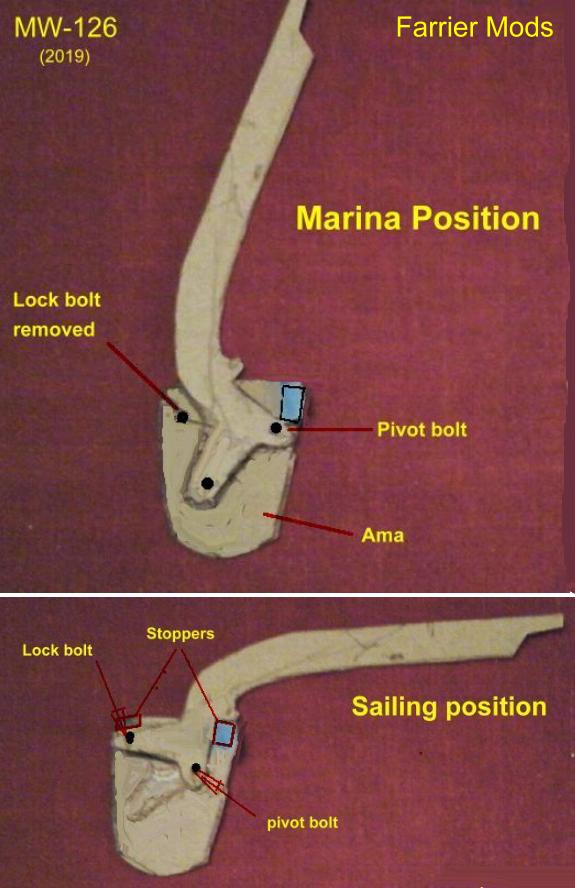

A review of the geometry shows that IF the ama could be left free to pivot while the arm is folded, it would take up a fairly level position and could readily be held there with a simple retaining line. (A possible solution is now entry #126 in an Ideas & Inventions Record Book I started back in 1952 ... with this one being 'just an idea'. Even a documented 'idea' needs to have a prototype built and proven to become an 'invention' ;)

To achieve this, several modifications would be required. While much easier to build-in during initial construction, it could be possible to retrofit an existing Farrier with some effort and ama surgery.

Here is what I am suggesting, though test experience could expect to bring about a few tweaks.

- Rectangular holes cut in the deck in line with the aka beams

- The installation of two heavily reinforced bulkheads or webs under the deck, both forward and after of each hole and added longitudinal reinforcements to compensate for the hole

- The attachment of a solid, strong foot-shaped part at the outer end of each aka .. solidly made of aluminum, fiberglass or carbon fiber and well integrated into the aka beam end. This foot would fit snuggly between the two new bulkheads and be drilled to take strong bolts through the heel and toe of the end piece. (see photo)

- The heel would have a semi-permanently installed pivot bolt, while the toe would take a locking bolt that would only be installed after the aka was lowered to the horizontal sailing position

- Naturally, hinged covers would cover the deck holes once securely bolted down, but if the area was created as a watertight well (like an anchor locker) with a drainage hole to the inboard side, that deck cover would not need to be 100% watertight.

- Detailed design would need to take care of bolt access and also of all loads typically expected on the ama.

It could be expected that initially, it would take about 20 mins. to attach each ama for sailing, but that this time could be cut in half with practice and planning, making the whole operation one of about 10 mins. for 2 persons. Probably worth it for the convenience of a flat deck in most cases and if fouling is not an issue, one may decide to turn only one side, purely for easier boarding. Just some thoughts to chew on ;) m/

.

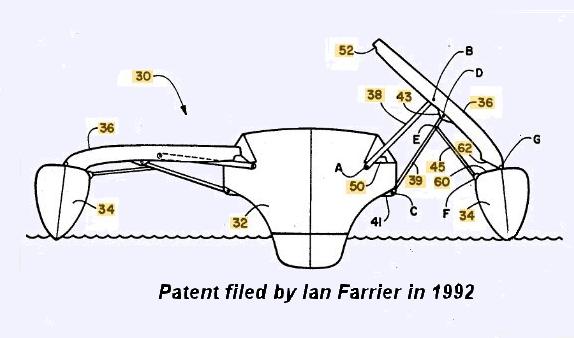

Postscript: (2022) Further research has brought up some interesting developments. First, that Farrier himself was working on solving the side-turning ama, as in 1992 he filed papers to Patent this modifcation to his original 1974 system. It involves added control arms under the main aka, that stabilizes a now pivoting ama that would then stay upright. See this sketch from the Patent papers.  But as this control arm would be rather exposed and the whole ama attachment not be as strong and rigid as before, I suspect that further development on this concept was postponed or even cancelled. However, Rapido trimarans, who quickly adopted the original Farrier concept for their Rapido 50, were pressured by customers to solve the fouling ama issue and came up with a pivoting one that lays just below the ama deck line .... seemingly not unlike the one I proposed above. In 2022 this was available for both their Rapido 40 and 50 models built in VietNam, but while clearly more rugged

But as this control arm would be rather exposed and the whole ama attachment not be as strong and rigid as before, I suspect that further development on this concept was postponed or even cancelled. However, Rapido trimarans, who quickly adopted the original Farrier concept for their Rapido 50, were pressured by customers to solve the fouling ama issue and came up with a pivoting one that lays just below the ama deck line .... seemingly not unlike the one I proposed above. In 2022 this was available for both their Rapido 40 and 50 models built in VietNam, but while clearly more rugged than the 1992 Farrier concept, only time will tell if this one has the strength and endurance of the Farrier original. Clearly not for very cold climates where icing could become an issue.

than the 1992 Farrier concept, only time will tell if this one has the strength and endurance of the Farrier original. Clearly not for very cold climates where icing could become an issue.

.

Click here for Part 1 of this article - comparing basic types

Click here for Part 2 of this article - comparing with demountables

Click here for Part 4 of this article - more options for the W17"New articles, comments and references will be added periodically as new questions are answered and other info comes in relative to this subject, so you're invited to revisit and participate." —webmaster

"See the Copyright Information & Legal Disclaimer page for copyright info and use of ANY part of this text or article"