Trimaran Folding Systems - more options — Part 4

.

W17 Gull-Wing to Demountable; plus the Four-point Swing Arm option designed for the W19 & W32

How the Gull Wing W17 can also be a demountable.

As regular readers will know, my W17 Magic was flipped upside down on a stony beach in a freak 2022 late summer windstorm.

It was easy to dismantle her by just pulling out the hinge pins, and then carry the lighter individual parts up the beach for checking and maintenance. To re-assemble her, I just aligned the aka hinges while the amas lay on the ground and then slipped in loose ¼” bolts as a pivot. I could then lift each ama, rest it on a prop, and install the original hinge pin above the beam to make her ‘whole’ again.

It all happened so easily despite assembling alone, that it occurred to me the boat could easily be considered a demountable as well as one with a folding system!

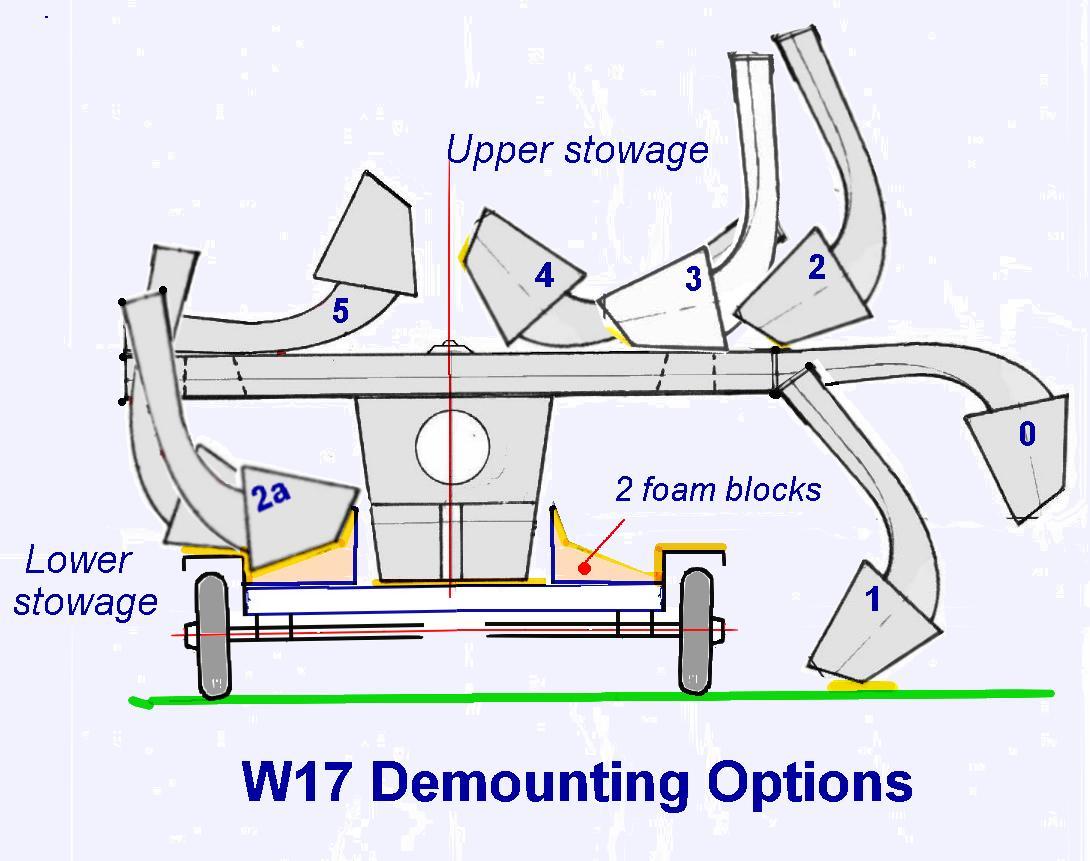

With that in mind, here is a sketch of two ways the amas might then be stored on a trailer. With props at hand, this assemble could readily be done alone, as each ama can be manhandled one end at a time, giving no load greater than 60lbs (27kg).

To dismantle, one would first remove the underside latch bolts and replace them with smaller 1/4” dia bolts (smaller pins are needed as the lower latches are not aligned ‘perfectly’ like the upper hinge pins, due to the different beam depths fore and aft. The misalignment across the latch will be under 1mm)

One then places a prop under the Ama Position 0 and removes the upper hinge bolts, allowing the ama to be lowered to Position 1. Then the temporary lower pins would also be removed and the ama lifted (could be one–end-at-a-time if alone) either up on to the central beams and cockpit (see RH side of skietch), or placed on the trailer bed (see LH side); both bedded on foam supports and positioned roughly as shown.

It’s a viable option if alone without the need to use the GullWing stowage.

=================================================================

Could there also be a Swing Arm Solution?

A few sailors, who love the look of the existing W17 design, have come to me with that question. Just a few have unique situations that gives need to a folding system that can be deployed when afloat, as their launching ramps have closed sides barely 3m apart, which means that the mast first needs to be raised and then, after passing down the narrow ramp, the boat is opened in the water to get the trimaran’s full sailing stability.

Both the Farrier ladder System AND the Dragonfly Swing Arm system would work for this, but BOTH bring a problem that the basic W17 GullWing does not suffer from. This is the extra spray that is created while sailing, with underbeam supports hitting waves; the solid arms on the Farrier’s and the waterstays on the Dragonfly’s. While it’s fairly minor from the wire waterstays, it can be annoyingly wet with the solid under-amas on the Farriers, Scarabs and others with a basically similar design, and would definitely destroy the present dryness of the W17, being closer to the water surface than on much larger boats.

Fortunately, I had already designed a swing-arm system for a larger W32 ocean-going cruiser and which is now an option for the W19 as well. So what is different about this design that can cut the need for waterstays? Let’s take a look.

On the W17, there are substantial box beams and in order to basically ‘slice them’ to reduce the beam, their top and underside members must be replaced with connections that are equally strong as the original beam. The hinges and latches designed for the W17 achieve that. With ‘box beams’, this ideally means tying together all 4 corners of the box. In the case of the Dragonfly, the upper and lower surfaces of each beam are of metal and bridged fore and aft by stainless steel, so physically can be linked to the main hull with only one bolt. But as one bolt provides zero redundancy, waterstays become essential. But if we can provide a bolted connection that ties together all 4 corners of the W17 box beam we will not need that waterstay, as the strength can be made as strong as if the beam were continuous and uncut ... as is the existing Gull-Wing system.

For want of a better name, I call this a Four -Point Waters Swing-Arm hinge. (Elsewhere referred to as WSA). For the Gull Wing W17. the upper and lower wood surfaces of the box are already strongly reinforced in way of the hinges and latches, having extra internal plywood gussets with layers of biaxial cloth. These are all ‘grabbed’ together with the palms of the fiberglass hinges by a substantial number of sturdy bolts or lag-screws that are all bedded-in with epoxy, reinforced with carbon fiber clippings. When made correctly, this creates an immensely strong connection that has proven itself with over 10 years of use without a hint of weakness. See Hardware Mounting for this joint.

-Point Waters Swing-Arm hinge. (Elsewhere referred to as WSA). For the Gull Wing W17. the upper and lower wood surfaces of the box are already strongly reinforced in way of the hinges and latches, having extra internal plywood gussets with layers of biaxial cloth. These are all ‘grabbed’ together with the palms of the fiberglass hinges by a substantial number of sturdy bolts or lag-screws that are all bedded-in with epoxy, reinforced with carbon fiber clippings. When made correctly, this creates an immensely strong connection that has proven itself with over 10 years of use without a hint of weakness. See Hardware Mounting for this joint.

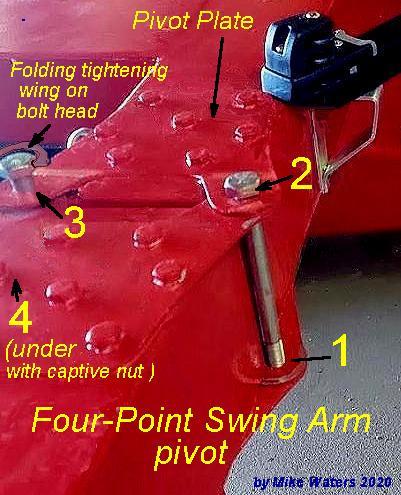

If we now replace the hinge and latch with horizontal plates using the same attachment to the beams, we basically have a demountable boat. But if we go another step and place a sturdy vertical bolt at each side of the box joint, we can create a Four-Point attachment that will achieve the goal of ‘tying together the 4 box corners’ but in a way that permits the outer beam arm to swing aft when the forward bolt is removed (see pic at right). Yes, this will be an additional step in the folding procedure but if this bolt is made self-aligning and fitted with a wing ‘handle’, it can be inserted and removed very quickly … with the advantage that no waterstay will be required for boats under 20ft.

As designed for the W32, the removable bolts have a fold down finger-wing at the top and the underside nut is captive in a fixed shroud for easy installation only from the top. In the case of the W32, I consider the addition of a waterstay very logical for further redundancy, something always advised for any ocean-going boat.

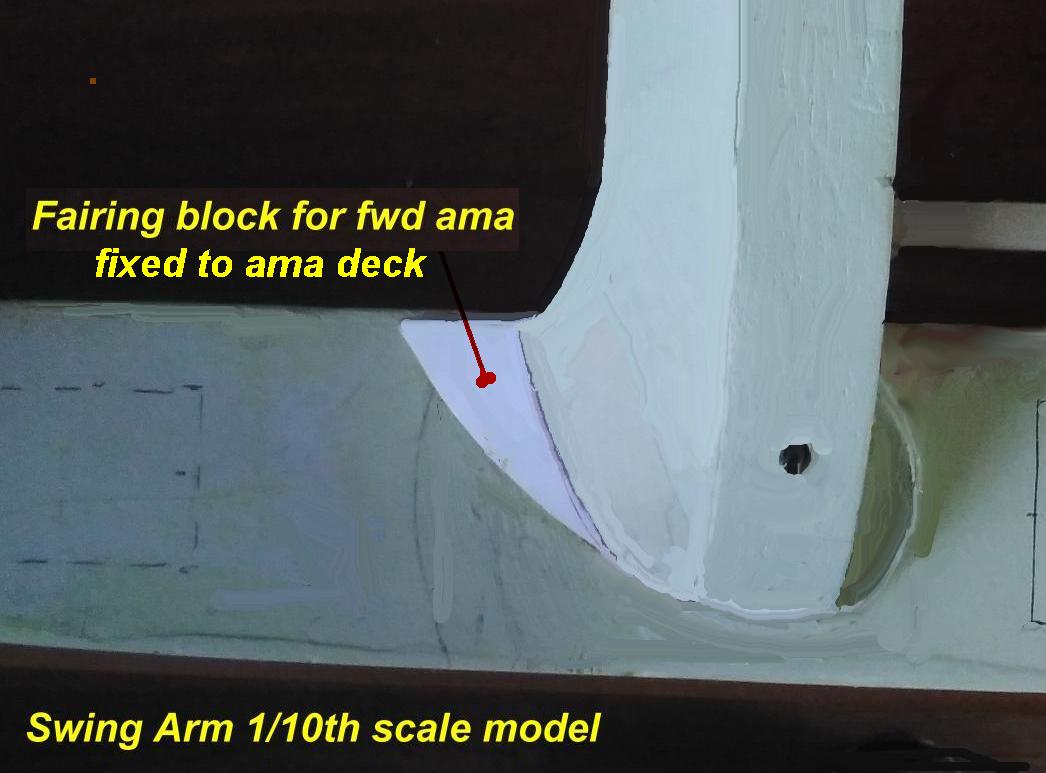

While mentioning the W3 2, one might note that the W17-style fairing, if left fully attached to the forward beam while folding, will project outboard and not only increase the width but be vulnerable to damage. This is solved on the W32 by removing the lower forward curved part and bonding it permanently on the inboard edge of the ama deck. See this image from a scale model. The base of the rotating aka is then raised to suit, with the under-surface interface angled slightly to give base clearance as the aka rotates aft, so opening a slight clearance gap to lower the rotational friction.

2, one might note that the W17-style fairing, if left fully attached to the forward beam while folding, will project outboard and not only increase the width but be vulnerable to damage. This is solved on the W32 by removing the lower forward curved part and bonding it permanently on the inboard edge of the ama deck. See this image from a scale model. The base of the rotating aka is then raised to suit, with the under-surface interface angled slightly to give base clearance as the aka rotates aft, so opening a slight clearance gap to lower the rotational friction.

.

Here is a cross section through the beam of a W17 using the Four-Point Waters Swing-Arm (WSA) with a shout-out to builder Rolf who patiently and successfully worked through this first installation. The horizontal plates can be of stainless steel, fiberglass or carbon fiber, with the latter two recommended for lower noise. The completed folded-in boat looks like this, with beam about 8ft. The fore-beam fairing can also be made totally removable if needed. or preferred.

The completed boat with the Four-Point Swing Arm, achieves the goal of retaining the popular appearance of the original W17, with just one noticeable exception. Due to the significant movement aft when folding, the outboard edge of the trampoline also moves aft and needs a strong line to tension it. It therefore cannot readily be attached to the folding ama, so it is typically left free as shown here. Another issue is that the center of gravity moves aft when folding a Swing Arm, so some means is needed to re-establish enough tongue-load on the trailer. Perhaps a couple of large portable water containers stowed up forward will suffice.

[In the above photo, while the temporary inner mast shrouds are in place, the main shrouds are not. Though shown as backstays here for temporary support, the boat will eventually use the standard bridle to both akas.]

But in closing, it's very important to balance the compromises before saying, “I want this swing-arm solution”. For a small tri like the W17, it’s more complex to build than the original, as well as more costly & heavier, plus the trampoline cannot be secured to the ama if folded regularly. So I would only recommend it when it’s absolutely your only launching solution, as it was in this case. This Four-Point Swing Arm (WSA) is far more justified on a larger boat however, when lifting or moving around the larger amas is no longer practical.

Mike ... March 2023

.

Click here for Part 1 of this article [Comparison of Farrier folding with Dragonfly Swing Arm]

Click here for Part 2 of this article [Comparison with Demountables]

Click here for Part 3 of this article [Hinge & Latch; Gull Wing & Telescoping beams]

this Part 4 [Gull Wing to Demountable & Four-Point Swing Arm]

still to come Part 5 [Flat plate Swing Arm]

"New articles, comments and references will be added periodically as new questions are answered and other info comes in relative to this subject, so you're invited to revisit and participate." —webmaster

"See the Copyright Information & Legal Disclaimer page for copyright info and use of ANY part of this text or article"