Fiberglass Latches & Hinges ... for the W17

By now, most W17 builders should be aware that a detailed 'fiberglass fabrication instruction manual' is now available for both the underside latches and upper hinges that make up the simple, inexpensive but effective folding system for the W17, and that this is now the most recommended way of hinging and locking (latching) the beams (akas) in place Not only does fiberglass offer a superior bond to the wood beams (compared to metal) but parts built this way are lighter, less expensive and corrosion proof. However, they DO take extra time and effort to make, so for those not wanting to go that route, the design and some availability for the optional stainless-steel latches, will still continue to be offered for the foreseeable future.

The optional stainless latches are defined on four DXF drawings that can be directly used for laser cutting of the parts. These dwg. files are included on the basic W17 Plans & Manual CD.

For the fiberglass latches and hinges, a separate Fabrication Manual is available with full details and photos by sending US$27 via PayPal to this email < trimarandesign AT earthlink DOT net >, following receipt of which, the PDF of the Fabrication Manual will be sent out, also by email. See photo of a latch to the right, prior to drilling the mounting holes.

Since this option has been available (2015), many new builders have chosen to build their own fiberglass units and a few photos are shown below. Prior to the final layer of biaxial cloth, it’s strongly recommended to take the time to ‘fair up’ the palm surfaces as well as the ‘fit’ of the inter-mating knuckles, so that the final result looks neat and professional. If needed, any corrections to the knuckles should be made as soon as any need is identified, so that the maximum number of glass layers are put in place after the shape and size is as designed and instructed in the Manual. This is the best guarantee of adequate strength. (One of the original latches was tested to destruction in a materials test lab and proven to meet the design load).

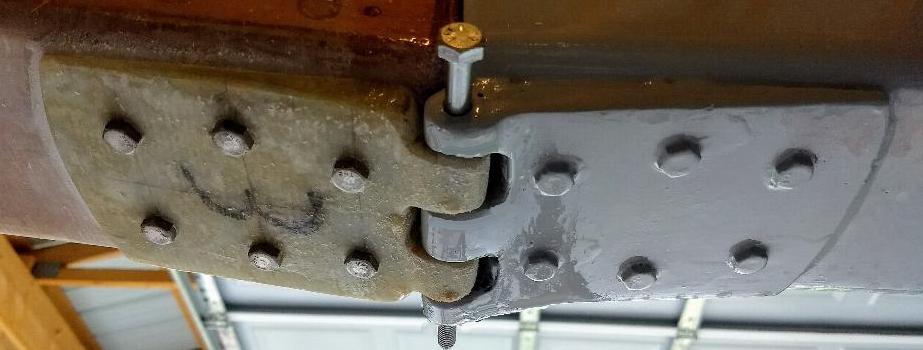

Here are photos of a few hinge/latch units as completed by different builders from the available instruction manual.

Set of latches already installed on the underside of the beam or aka

--- Pieces of UNI and biaxial cloth, ready for wrapping over the hinge/bolt assembly .... see Manual.

| <-- Set of small home-built parts prior to molding of the hinge palms – all detailed in the Manual. |

| A neat set of latch and hinge blanks ready for final fitting at the knuckles. |

www.smalltridesign.com

Feel free to send in specific questions or comments via my Questions Form, that I may select to answer through this webpage if considered of broad interest.

"See the Copyright Information & Legal Disclaimer page for copyright info and use of ANY part of this text or article"