What reaching sail should I fly (or buy) ...... ?

QUESTION: "For my fairly small trimaran, I am looking to expand my basic mainsail and jib rig with a reaching sail, but am confused by all the options being offered. Can you please help explain them so that I can make a wise choice ?"

Paul-L, USA

ANSWER: To do this, I need to dig into foresail options in some depth, but I hope this will help clarify the options.

.... mike

.

An in-depth review of FORESAIL TYPES

. . . . . . . what they are called and when to use them

INTRO

While we all probably know something about mainsails and jibs, many other sails have appeared in the last 20 years or so, and most of these are foresails to improve off-wind performance in a range of winds

After looking over what the well known sailmakers are offering, it’s rather clear that there is no real standard across the industry so this has become rather a marketing battle, with each maker designing their own twist on each basic type with names to catch the imagination and hopefully convince buyers that their specific sail (and how it’s rigged) has that extra magic to be ‘just that little bit better’ than the competition. But let’s at least try to define ‘the basic types’.

For decades back, there were 4 base sails; main, jib, genoa and spinnaker, (plus a storm jib and trysail), whereas now, in the drive for higher speed and efficiency, there are perhaps 20 foresail variants.

I had hoped that North Sails, one of our present-day leaders in sail development would have the new types all clearly defined, but on review, one has to look far beyond one sailmaker to touch all the options, so to get a fair cross-section, I’ve explored North, Evolution, UKSailmakers, Quantum and Doyle for their personal definitions, but be warned, it’s something that is still changing a bit every year and it can indeed become highly confusing. But as an independent voice not exclusively endorsing one specific sail or designer I will make an attempt to define the various sail types and what sailing angles & wind strengths they are designed for, in a way that the majority of sails offered can fit-in with the overall scheme of things, but as there will still be exceptions, I will identify those I see, separately.

GETTING STARTED

First, let’s simply define a FORESAIL as a sail with its leading edge (luff) totally ahead of the mast. Starting with that we have two main variables that control foresail shape both in camber and profile .and these are; their angle of operation relative to the wind (starting from the wind ahead or bow-on position) and the wind force in which they are to be used with most effectiveness. I should also clarify here that the ForeTriangle is the triangular space typically defined by where the foresail Tack (fwd lower corner) is attached to the boat, the Peak or Head, where the halyard block is on the mast, and by the forward face of the mast at the foot. A sail Profile, can be taken as the side view as seen on a Sail Plan. Finally, the distance from the forward face of the mast to where the headsail is attached on deck is the ‘J’ dimension often used as a guide when defining racing-boat rigs. And I use MHG for the ‘mid height girth’. If the Leech and Luff are straight, then the MHG will clearly be 50%. But on spinnakers, asymmetricals and Code sails, there will typically be added Leech Roach and Luff Roach that will increase this percentage.

SAIL / WIND NUMBERS

As far as wind force is concerned, most of the foresail sail types can be defined with a NUMBER as a suffix (added on), starting with #1 for the lowest winds that are of light material and cut with deep body (thus being more powerful), and rising to #5 for the flattest, strongest but smallest. (‘Deep’ in this context, means full cut with lots of camber and ‘powerful’ typically means the shape traps more air for propulsion and creates more lift … something desirable for light winds but less practical for heavy ones). As a rough guide, we can take each No. to represent about 7 kts, of wind, with a typical +/- range of either 15% or 4 kts. whichever is the greatest. So as an example, a #2 sail will likely be designed for ~14kts of wind +/- 4 kts, so idealized for a range of 10-18kts, while a #5 sail calculated the same way would be designed for high winds in the 30-40kt range. While the former sail could be of fairly full cut with a wide profile and moderately light material, the latter would mean a flatter cut, smaller profile and stronger cloths. But the cut, camber and profile will be further defined by its Sail Type. This numbering can apply to all types of foresails from Jibs (J1, J2 etc), Genoas (G1, G2 etc) to Asymmetricals (A1, A2 etc), though there is ‘an exception to the rule’ that I will explain later in this article.

Before we dig in further, lets summarize the general types and sizes of Foresails

- If equal to or smaller than the Foretriangle … it’s a JIB

- If the foot exceeds the ‘J’ dimension by say 10% or more, and the mid-height girth is not greater than about 52% of the foot, it’s a GENOA when the luff is rigid or wire mounted for upwind work.

- If the mid-height girth is greater than 75% of the foot, it’s a SPINNAKER.

- Between the Genoa and the Spinnaker lay all the asymmetricals, screechers and Code sails, with asymmetrical profiles, showing both rounded luffs & leeches. These are all for reaching between 50 and 150 degrees off-wind in various wind conditions. But the old classic spinnaker is still king for 150-180 deg.

SAIL TYPES

Let’s start with wind ‘hard on the nose’ for various designs of boats, being ‘close-hauled’ or ‘going to windward’ at angles of 35 to 45 degrees from the wind. (Of course this excludes ice yachts and foilers that can create an apparent wind much finer than that).

To be most effective in this direction requires a tight luff that can be finely edged into the wind without risk of collapse. Typically this is a luff with a wire (often hanked to the forestay) or attached to a semi-rigid foil (alum or plastic over a wire) that will stay pretty straight .. typically using a bolt rope hoisted up inside a tube, much as many mainsails are attached to their mast...

The smallest of these sails is our common JIB and can vary from a miniscule Storm Jib that is typically more for control (tacking etc) and balance than sailing power, up to a full jib of 105% (max. 110%) of the Foretriangle (FT).

Anything with a longer foot is called a GENOA, but this is also a sail with a taut (tight) wire luff for sailing to windward. But because this sail gets progressively harder to sheet flat (to point close) as it gets bigger, the larger genoas (say 140-160% of the FT) are generally limited to moderate wind conditions.

Just a side note re Genoas: I personally think its very justified to use hi-end material for a genny, as the high loads will more easily deform cheap material and immediately reduce your upwind ability. More critical, I believe, with a foresail than a mainsail where the mast takes much of the load off the sail, except for the leech, where for a wingmast sail, I always specify 'a twin-ply leech' (a fairly wide doubler to better resist vertical tension). To reduce the sheet-load issue, an interesting foresail to sail tight-on-the-wind in light weather, might be what I will call a G-0 .. a 115-120% Genoa set to a near masthead sheave, giving a long-luff high-aspect sail with a flat leech that could readily be firmly sheeted, with its attack angle adjustable with a barber-hauler. (See Sailing Tips Part 1 for definition).

As your boat eases off the wind, we reach a condition of Close Reaching, starting say at 50-55o off the wind and we can start to use lighter materials with more shape and size to great benefit. The most important breakthrough for this has been a sail called a Code-0, so let’s first explain how this started.

Because conventional spinnakers were typically only used downwind, the carrying of one on a raceboat did not add a large rating penalty as they did not see a high percentage of use, so most boats carried one. But to be defined as a spinnaker, the mid-height girth (measured width) had to be at least 75% of the foot (typically a full downwind race spinnaker is much more than that with its width typically 180% of the above defined ‘J’ dimension).

But to help with reaching (first on Volvo and America Cup boats), it was decided to make ‘a flatter spinnaker’ at the minimum mid-height girth (MHG) of 75%. but set it with one edge always being up forward. Such a sail would no longer be symmetrical so the after part could be cut flatter than the forward part, even if both the forward and aft edges would need to be rounded-out in profile to give the required 75% MHG (to pass rules as a spinnaker) so a dedicated Luff and Leech was created. The other great advantage was that a pole would no longer be required, especially with boats getting wider. This sail is the one that became the CODE-0 and because it is set without a pole, can readily be used when sailing solo and with their width, is a natural for multihulls. It’s still a very popular choice for reaching in light and moderate winds, especially since sailmakers have found several ways to furl them, despite their rounded luffs.

Since then, some countries have modified their rating rules to allow a Code-70 (or even a Code-65 in Denmark) to be considered a spinnaker, so more Code sails have now been developed for closer reaching angles and higher winds with the later ones now named/defined by the width % of their MHG relative to their foot dimension. (Because these asymmetrical sails have a rounded cloth luff without a tight wire, they are best set with an adjustable downhaul to the forward sprit so that this flat entry cloth can best interface with the apparent wind without collapsing.. Typically this means easing this downhaul in both light and strong winds but tightening somewhat more in moderate winds, something that will vary with each sail and wind angle).

Of the asymmetricals, the Code-0 is the closest to the genoa being the flattest, so can also be called a Gennaker. When set on a Multihull, these relatively flat Code sails are often called Screechers (due to the high reaching speeds they can produce) though a multihull screecher will typically be cut even flatter. This is because they can be of even more help to go upwind in light airs, as multihulls that tend to have small jibs are proportionally under-canvassed in light conditions. For windier conditions, slightly smaller Code sails are now also available as shown here …. now defined by their MHG, from which we can see that a Code-0 could also be called a Code 75.

For even more power when sailing in a wind farther aft (Broad reaching), a whole family of Asymmetricals has now developed called the A1, A2, A3, A4 etc The light wind A1, is both larger and fuller than even the Code-0.and these are typically flown from the mast head that allows considerably more area.

Again, the higher suffix implies a tougher cloth, smaller size and less depth for higher winds. (but see Exception below). As racing boats need to sail at their best speed at all angles to the wind, what sails they carry will mostly vary by storage space, crew and funds available, but for a cruising boat on both ‘tight space and budget’, it will depend more on whether their time spent in one direction relative to the wind, really justifies a unique sail for that purpose. Many sailors need to consider that. The fact that the Code-0 can sail on a close reach yet still help out at broader angles and can even be set singlehanded, has made it a versatile and popular choice, although it’s still for light to moderate wind only. The fact that this sail is ‘relatively’ flat (has meant that it can even be used with a furler though sailmakers constantly compete to find the best way to make this happen. (I will not get into this complex subject here, except to say there are furling systems with a wire inside a luff pocket or those with stiffened ‘structural’ luffs; with furlers that start the wrap from either the bottom or the top, so again, ‘it gets complicated’.) But the long foot demands using a furler with an endless control line, and having an adjustable downhaul is almost a must… see photo.

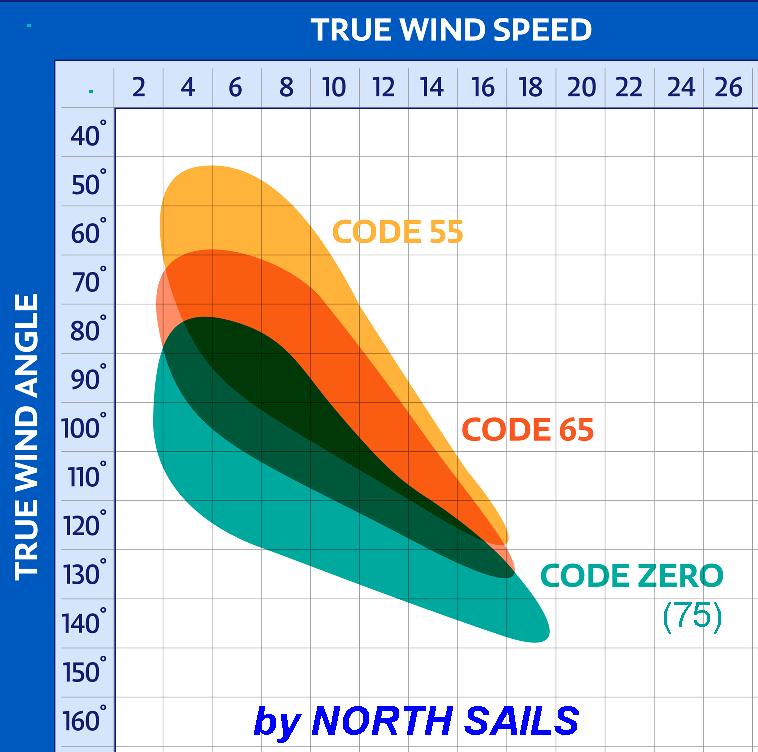

It’s also clear that not every sailmaker has the same approach to creating their Code sails. North for example, seems to go with a fuller model than say Quantum, so their Code-0 will be less comfortable trying to sail on a close reach but more performing downwind. This diagram by North shows that their Code sails (shown in grey above) can just about be carried with ‘their angle off the wind’ equal to their Code-No. ie: say 65 degrees minimum off wind for their Code-65. A convenient reference but pure coincidence, as the number comes from their MHG. But I’d say this relative fullness better suits a slower mono than a multihull, though I am confident North Sails would adjust for this.

every sailmaker has the same approach to creating their Code sails. North for example, seems to go with a fuller model than say Quantum, so their Code-0 will be less comfortable trying to sail on a close reach but more performing downwind. This diagram by North shows that their Code sails (shown in grey above) can just about be carried with ‘their angle off the wind’ equal to their Code-No. ie: say 65 degrees minimum off wind for their Code-65. A convenient reference but pure coincidence, as the number comes from their MHG. But I’d say this relative fullness better suits a slower mono than a multihull, though I am confident North Sails would adjust for this.

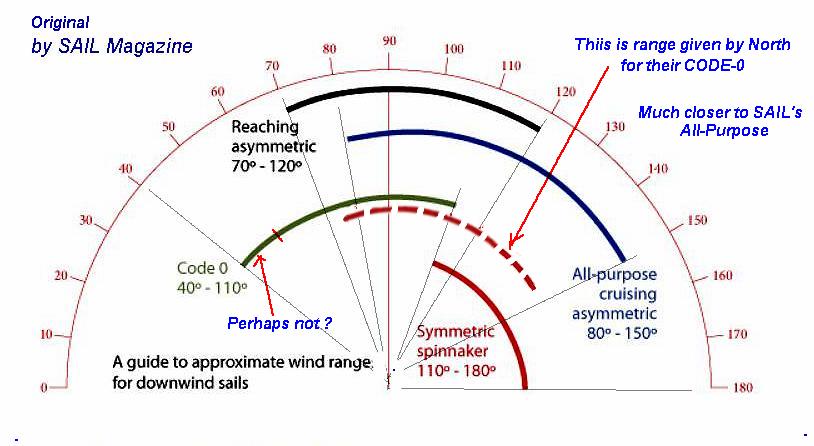

But for a more ‘overall’ picture of where these various Foresails fit on the wind scale, ‘an image is a 1000 words’, so here is a diagram originally published by Quantum Sails (to which I have added some text and numbers for clarity). This shows the range of angles and wind force for most of the sails noted above.

To follow how this works, let’s look at the example of their Code-0 as plotted.

I have placed a few Red Dots around the zone periphery for points to mention.

First, note the barely visible ‘wind-speed rings’ that radiate from ‘the boat’. Sails shown closer to the boat are for light winds. The other aspect we mentioned at the opening of this article, was the angle a specific sail could operate at, relative to the wind. This angle is shown by the radial lines and I have marked in a few values.

So this Code-0 (as defined by Quantum in this case), can start in very low wind speed, sailing as close as a 60 deg. heading (other makers may even ‘claim’ 50 deg). .

As wind increases to say 8kts (2nd red dot), we would now need to bear off to 90o.or switch to a Genoa or Jib to best hold this course.. This trend continues, so with 14kts of wind we have to bear off to 120o or ideally change to a #2 Jib, and to handle its maximum wind of 22 kts, we’d need to bear off to nearly 150 degrees, when a smaller Code 65 or 55 would certainly give us more breathing space.. Once over 100o off the wind, Quantum are showing a Blaster or Screecher (in purple), that being of heavier material would better handle the higher wind. To go to windward in that wind force would ideally require a #4 Jib as per this diagram.

(In case you wondered .. the "Fr0" sail (in red) is a Code 0 mounted lower down on the mast ,, ie: a 'Fractional Code-0'. While this is typically done to have less sag in the luff to point better upwind, the Quantum Diagram shows it targeted for stronger winds more downwind and not for its potentially better pointing ability ... 'go figure', is all I can say. Yet another inconsistency between sailmakers)

Here is another diagram … this time by the reputable SAIL Magazine. Here they even show a Code-O working down to a 40 degree heading to the wind, which I personally find hard to believe. But even if we clip this to 50 degrees, there’s still a large gap to what the North Sails range shows .. which I have added here in dotted line. Ignoring the 40 deg. claim, this does not automatically mean any error or false claim, but only that the form standards particularly for the Code sails are clearly very broad, and one would need to work closely with your chosen sailmaker to have your sail cut for what will serve you best on your boat.

It should be clarified that foresails on wire stays or others ‘flying free’, do need totally different sail structure. The jib and genoa are well supported at their luff so their sail structure needs to be ‘leech based’. But the ‘free flying’ foresails are missing direct stay support, so need to be ‘luff-structured’ to compensate. These typically include the screechers, asymmetricals and Code sails with the possible exception of very light wind sails that are not stressed.

It should be clarified that foresails on wire stays or others ‘flying free’, do need totally different sail structure. The jib and genoa are well supported at their luff so their sail structure needs to be ‘leech based’. But the ‘free flying’ foresails are missing direct stay support, so need to be ‘luff-structured’ to compensate. These typically include the screechers, asymmetricals and Code sails with the possible exception of very light wind sails that are not stressed.

While initially (and mostly still) such sails are hauled-up like spinnakers, speed, safety and convenience has put pressure on sailmakers to create imaginative ways to use them with a furler so out of this has comes the Helix Structure (by NorthSails), as well as equally viable options from Quantum and Doyle that help such sails furl more successfully. In a few words, the forward part of the sail has strong strands that work in a tension spiral as the furler is rotated, bringing a wider part of the luff fabric with it, so compensating for the lack of a turning wire or foil. Sailmakers have also done work to spread the vertical luff load over a much wider area so that the actual luff load is much less. This allows the rounded luff to 'present itself' better to the wind without as much tension.

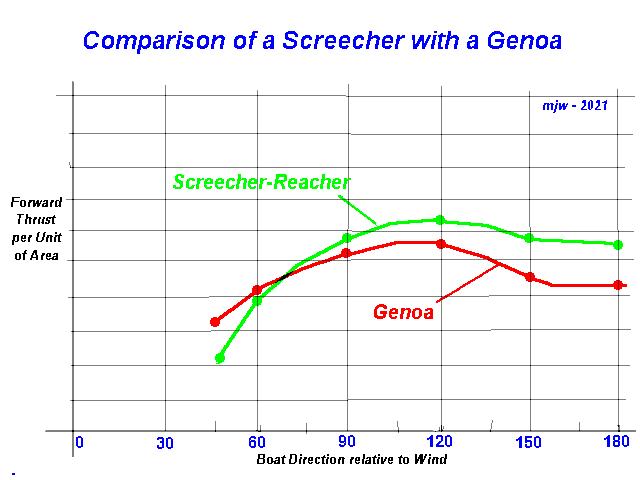

Contrary to the classic upwind genoa on a wire, Code-0 reachers and screechers are to improve speeds when more off the wind, which brings me to share this little diagram to show how I personally see a Genoa might compare to a Screecher for a trimaran like the W17.  Both these curves are based on generally accepted ‘sail thrust values relative to wind angle’. While I have no test results to give precise figures, I believe the trend shown is reasonably viable. Here we see that the Genoa is more effective for close-winded sailing up to about 70o, but if you need more reaching power, then the Screecher would be the way to go.

Both these curves are based on generally accepted ‘sail thrust values relative to wind angle’. While I have no test results to give precise figures, I believe the trend shown is reasonably viable. Here we see that the Genoa is more effective for close-winded sailing up to about 70o, but if you need more reaching power, then the Screecher would be the way to go.

As noted before, a ‘Screecher’ might fairly be considered a slightly flatter Code-0 to suit the higher speeds of say a multihull, with its cut being closer to a Code-55/65.

It also likely that the Screecher will be shaped rather more like 'a wireless Genoa' than a spinnaker or Code 0 for a mono. With the latter being carried at deeper angles (say over 120deg as per the North Sail diagram above), the leech can be somewhat tighter (more spinnaker-like), but with the Screecher, its preferable to have the leech flatter to avoid backing the mainsail at the tighter angles.

EXCEPTIONS

Earlier, I had mentioned that there are exceptions to the number coding,.

Here is an important one to note.

For both the ‘A’ designated Asymmetrical spinnakers and Code sails, these fall into five mold shapes (A1-A5 etc) to suit different wind speeds and angles, but in this case the even numbers designate running shapes and the odd numbers are reaching sails, so the progression of Reaching Asymmetricals goes A1, A3, A5, with the Running sails being A2 and A4. (To make up for only two sizes for running, some sailmakers now offer a A1.5 running sail for light winds)..

To have an idea of size, an A3 spinnaker has a MHG of about 80-85%, while an A1 may have 90-95%. The somewhat flatter Code sails can also use a similar number designation with C1, C3, C5 being for reaching and C2, C4, C6 being for running.

SHAPES - a few thoughts

If a very light wind sail is too wide high up, the sheer weight of the fabric will not help it stay open so such sails often have what are termed ‘narrow shoulders’. If the sail is needed to deeply broad reach, then a wider sail with a higher MHG will give a better chance to grab air from the windward side so these sails are generally near maximum width. The closer the reach, the flatter the luff must be and in heavy weather, when the fullness of a lightweather sail would overpower both the sail and the boat, it must be cut flatter to spill the excess wind thrust and will then be more stable and easier to control.

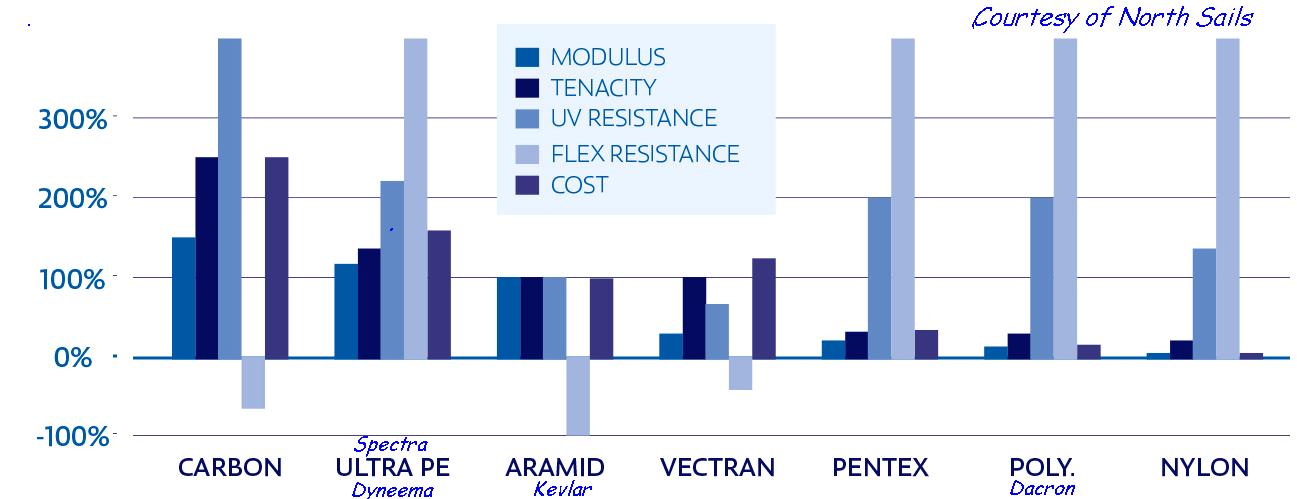

SAIL MATERIALS

As this seemed a fair summary of now routine sail materials that North Sails has published, I am reposting the relevant part here for which we must give them full credit and thanks. But they are not the only supplier/user of good sail material and I would add on the PEB/PEX material (that HYDE also offer) as a laminated mylar sail material by Dimension-Polyant GmbH. with aramid and polyester fibers, as just one interesting and reasonably affordable example.

Polyester has for decades been the most commonly used sail fiber because it is strong, durable and relatively inexpensive. Woven polyester sailcloth is often Dacron, in reference to the brand name given by DuPont to their Type 52 Dacron yarn, which was developed specifically for sailcloth and was the industry standard for years. [Ed: Terylene was another one in the UK]. Over the years other suppliers have introduced premium polyester yarns well suited to sailcloth. Premium polyester yarns deliberately feature very high shrinkage when heated during the finishing process. High shrinkage, combined with very tight weaving, produces sailcloth which is tightly packed and stable without having to rely on on adding excess (and less durable) resins for stability. Polyester fabric is used both as stand-alone woven cloth and as a component in laminates. Polyester yarn is quite resistant to UV damage.

Nylon is widely used for spinnakers and asymmetric spinnakers (Gennakers™) because it is low cost, is lightweight for its strength, and exhibits good UV stability. Nylon is quite stretchy (a big part of why it has very good strength), which is not a liability in downwind sails [Ed: where some sail stretch is even desirable to absorb gusts that just cannot be avoided}. (Warning: Bear in mind: that while nylon is a rugged material, it is very susceptible to damage from exposure to chlorine so never use bleach when washing or rinsing nylon sails, and never soak a nylon sail in a swimming pool).

Aramid fibers are lightweight, have high resistance to stretch and high breaking strength. Not surprisingly aramids are often the fiber of choice for racing sails, and can also be viable in laminated cruising sails, when properly protected from excess UV and flexing. Kevlar® (a Dupont product) and Teijin’s Twaron® and Technora® are commonly used aramid fibers in sails. Aramid fibers are often blended with even lower-stretch and higher strength carbon fibers within the same racing sail. While not inexpensive, aramid fibers are moderately priced in comparison to the most exotic fiber types.

Ultra PE (UHMWPE) was originally introduced as a competitor to Kevlar. The brand names Dyneema®, produced by the Dutch company DSM, and Honeywell’s Spectra® are familiar to many sailors. These fibers are highly processed polyethylenes which offer very good UV resistance, very low stretch and very high breaking strength. Ultra PE fiber does exhibit some tendency to “creep” (elongate over time when kept under sustained high load). As a result the UltraPE mass in sailcloth needs to be relatively high compared to expected sail load. “Spectra/Dyneema” has been used primarily on larger cruising boats where reasonable weight, strength and durability are paramount. Ultra PE fiber is expensive, but very long sail life ensures high value in these sails.

Carbon Fiber appeared in sails during the 1992 America’s Cup and has since been widely accepted in grand prix sailing – including high end cruising applications. Carbon fibers are impervious to UV damage and have extremely high modulus (low stretch), but are quite sensitive to flex. If you take a raw carbon fiber tow (yarn) and fold it in your fingers it will snap after only one or two hard folds. Depending on the carbon content and the construction of the sailcloth, crews need to be very careful to avoid flogging and hard creases when flaking or folding a sail. A notable breakthrough in the utilization of Carbon is in blending it with Ultra PE fiber where the two material’s complementary properties are synergistic.

PEN, sold under the brand name of Pentex™, is available in a relatively limited range of yarn sizes. PEN fibers are related to polyester (PET) but stretch about half as much (PEN is only 1/5 higher in strength). This relative mismatch between stretch and strength performance means a PEN based sailcloth cannot be truly lightweight in actual use. The cost of PEN falls between polyester and the aramids. PEN use is mostly driven by class and rating rule restrictions where aramid fiber is not allowed. PEN fiber has low shrinkage when heated during finishing, so it cannot be woven tightly like polyester. For this reason, PEN fibers are found only in combination with PET (aka “mylar”) film in laminate cloth for paneled sails. (PEN does not come in woven form).

Two of the strongest materials for sails, aramid (Kevlar, Twaron etc) and carbon fiber, have 2 major problems though. One is that they are very expensive .., like up to 10 times the cost of polyester (Dacron), and the other is that they are miserably poor in flex, meaning that a few sharp bends in different directions can totally fracture the fibers. For this reason, they are not recommended for sails possibly flogging in very high winds or needing to be reefed and must be treated with great care when lowered and stored. Ideally they should only be rolled. Because of the flex-fraction risk, they are in fact prohibited for use in all storm sails.

Code-0 summary

I think you will find this short on-line summary by one sailmaker of a furling Code-0 of some value, but although they confirm this sail can be furled, do not leave the sail up. Once furled, bring it down to not allow wind to unwind or jamb part of it, and to also prevent it from long UV exposure.

The Code 0 asymmetric is a tight reaching sail, that can replace the jib for light upwind work in addition to many off wind angles. The luff is as straight as possible, and the sail is flatter than other asymmetric spinnakers. Due to the flatness of the code 0, it is usually made with a high modulus luff line for supporting strength, and of a heavier, less stretchy fabric than normal for a spinnaker. (ie: a polyester rather than nylon that is very common for spinnakers) Due to the tight luff and flat cut, the code 0 can be fitted for roller furling.

--------------------------------------------------------------------------------------------------------------------------------------------------------------

FOOTNOTE:

As regular readers will know by now … I strive to only post content I can vouch for. On most pure design work I have a long, qualified background tempered with significant on-water experience, but sometimes a subject comes up that has changed so much since I 'officially retired' some 20 years back, that I need to research it to be updated.. Because I generally know where to look and what to look for, it's normally enjoyable and not difficult, as I expect and typically do find that the correct answer is one consistently backed by several qualified sources. But this article on Sail Types has been a challenge. Despite getting data from top brand companies, I have struggled to find solid agreement over the new sail types, even if I just pick on one sail design such as the popular Code-0. The graphics I've reviewed (with a few shown here) show quite different operating ranges, which of course means that the shape of the sail body will need to be very different too. However, with some exceptions, I did find enough consensus to complete the article.

But if planning to buy one of these sails, it’s clearly important that you chat with your chosen sailmaker to be sure you BOTH understand what wind force and pointing range you actually wish to use the sail in, so that regardless of what your sailmaker actually ‘brand-names’ the final sail, at least it does what you want.it to. I just hope I have clarified, not added to. the confusion that seems to exist between these otherwise interesting asymmetricals

In closing, if you are not entirely burnt out and still ready for more, here are three articles from the many I’ve read that I found particularly worth reading. Even if targeted for those sailing larger boats, there are good facts here from which to take valuable knowledge. So enjoy !

A 2021 interview with Quantum-Sails VP of Production Integration and Sail Design

An article by SAIL Magazine on how to handle light air sails

https://www.sailmagazine.com/diy/light-air-sails-and-how-to-handle-them

Back in 2019, Sailing World wrote ... "Furling headsails are the future"

https://www.sailingworld.com/furling-headsails-are-future/

.

.

Now, before someone says, "well fine but, What about MAINSAILS ?" I will share with you a link to this Summary

by sailmaker Brian Hancock, as published in SAIL Magazine. It's a 2017 article but still mostly viable and clearly written.

Mike ..... Dec 2021

.

"New articles, comments and references will be added periodically as new questions are answered and other info comes in relative to this subject, so you're invited to revisit and participate." —webmaster

"See the Copyright Information & Legal Disclaimer page for copyright info and use of ANY part of this text or article"