Tips on Sailing a Small Trimaran

Part 1 Adjusting & Setting sails + Boat trim + Sail trim + Boom or Boomless etc

Part 1 Adjusting & Setting sails + Boat trim + Sail trim + Boom or Boomless etc

Builders of the W17 will one day appreciate to know how to sail their boat to advantage, so after spending a few seasons putting over 1200 nautical miles on my own W17R, here is what I can share. Even if one might claim I’m biased, I can honestly report that ‘Magic’ is one of the most satisfying boats I’ve ever sailed, providing a blend of performance excitement with dryness & comfort that is rare to find. It’s no secret that I personally enjoy ‘a sense of high efficiency’ in any boat, so here is what I have learned to date about how to achieve that on this boat. I share this broadly as I’m confident much of it can also help owners of other small sailboats to get more out of their chosen craft. Having said that, I’m confident that some passionate duo of 30 year-olds with 20 years of racing behind them will find even faster ways to propel this boat, but when this happens, I just hope they will share their secrets ;-) In the meantime, here’s what I have so far.

To some, much of this exposes nothing surprising but I still think it’s worth spelling out - for those either ‘a little rusty’ or more particularly for those into trimarans for the first time. Keep in mind that what is described here is about ‘efficient sailing’- ie: how to get the most out of your boat. Of course, one could ignore such performance gains and just laze around on this very stable boat, simply playing the control lines for safety reasons – but that is not what drives this article. This is about sailing efficiency & performance, requiring a little more attention and effort than just a social sail might inspire.

Before getting into boat trim etc, let’s chat about SAILS ... sail shape to be precise. Novice sailors are too often seen with poorly set sails. ‘Sails’ are your engine and poorly set ones are like running with only half of your cylinders firing. Should you notice that in your car, you’d head straight to a garage, yet when sailing, many seem to just accept the status quo. Let’s try to change that and expand your sailing pleasure.

We must first note that our power comes not only from the wind. Its interactive force is also significantly affected by boat speed and direction so let’s think of it as ‘air movement relative to the boat’ (or for many, the apparent wind). Take a simple example. Upwind, our boat speed will add to the air speed, whereas downwind it will deduct from it. This will also significantly affect the direction the air actually impinges on the sails. This in turn affects its drive, required sail shape and its ideal trim relative to this moving air. But more on this later.

Basic Sail Attachments

Although most modern sails have their leading edge attached to either a wire (foresails), furler track (reefable foresails) or to a mast slot (via rope or slides) for the mainsail, sail loads are still principally transferred to the spars and boat by their 3 corners, so the tension adjustment of each is critical for optimum performance. Here are these 3 key attachments (see sketch).

The halyard hauls and holds up ‘the head’ or peak. A line, shackle or pin holds on to ‘the tack’ (the lower forward corner of the sail) and with mainsails, there’s also typically ‘a Cunningham’ down-haul tackle to add more vertical tension to the Luff (forward edge of the sail) after the sail is hauled up. The aft lower corner (the ‘clew’), is either pulled rearward by an outhaul along a roughly horizontal boom, or in the case of sails with boomless foots (such as jibs or foresails), it’s pulled simultaneously ‘aft and down’, with a control line called a sheet. In the case of sails using a rigid boom, this ‘sheet’ leads from the boom and down to the boat on the downwind (leeward) side, which will depend on which tack the boat is sailing. As there’s a lot of tension in this line in strong winds, this sheet typically passes through multiple blocks to increase its mechanical advantage and lower the pull required. Even on a W17, the tackle for the jib sheet is a 2-part, while the tackle for the mainsheet is a 5-part in order to be able to apply sufficient tension by hand in strong winds. See here …….

(In the mainsheet photo to the right, note the small net of poly-mesh that catches the W17 traveler control line P&S to prevent it dragging in the water! Simple to make & install, hooked to track brackets & quickly removable).

Sail tension & shape

As a general principle, the stronger the wind, the tighter you need to set most adjusting lines. Primarily, wind travels horizontally over the water so the flow of the moving air requires that we look at the section of our sails in a horizontal plane, but as wind speed is greater at more height above the water surface, we also need to allow for that when trimming our sails. Sails are designed, cut, sewn and set, to give some camber to their horizontal shape …. much like the upper surface of a plane wing. Slower planes need more camber than fast ones … and so it is with sails. So a higher wind (or a faster boat - like many multihulls), needs a sail with less horizontal camber than in a lower wind or for a slower monohull.** This also means that the slower air down by the boat or boom, can accept more sail camber than higher up. This often appears to be ignored by many casual sailors and even some sailmakers, as I too often see sails that are made and set too flat low down for my personal preference. So particularly with full-length battens, a very tight outhaul along the boom is seldom required even for a fast boat, unless the wind is really howling (see next paragraph). However, higher up the sail, wind speed is faster so we need to reduce the camber and with a non-flexible wingmast, this can typically only be done by the sailmaker (using good panel design and stretch-resistant materials), though it can certainly be helped with stiffer, tighter, full length battens. I often add tows of UNI carbon fiber to the after half of full-length battens that are frequently too flexible there and it’s proven to be well worth the effort.

** (This is one important reason that multihulls needs sails made by makers who are experienced with multihulls. Also, as a wing-mast is very stiff fore & aft, the correctly matched mainsail will have an almost straight luff, with only the tack (fwd. low corner) cut back a little, so when the foot is pulled forward, this helps give more fullness, forward and low down).

The after half of nearly all aerofoils are almost flat but having underlined how critical the correct camber is, it’s still amazing to see some sailors seemingly quite unconcerned about this, even allowing the leech (rear edge) to curl to windward. As I like to visualize the air coming off the rear of the sail as a jet, the ideal direction is clearly one roughly parallel to the boats centerline. I have seen badly curling leeches with full-length battens that are far too soft, with leech lines too tight and even with a tight boom lift caught up in batten-ends as shown here. Such a ‘topping lift’ should never be the cause of any poorly set sail, as it’s an easy fix to just slacken it. Such a sail will take you no-where fast.

The after half of nearly all aerofoils are almost flat but having underlined how critical the correct camber is, it’s still amazing to see some sailors seemingly quite unconcerned about this, even allowing the leech (rear edge) to curl to windward. As I like to visualize the air coming off the rear of the sail as a jet, the ideal direction is clearly one roughly parallel to the boats centerline. I have seen badly curling leeches with full-length battens that are far too soft, with leech lines too tight and even with a tight boom lift caught up in batten-ends as shown here. Such a ‘topping lift’ should never be the cause of any poorly set sail, as it’s an easy fix to just slacken it. Such a sail will take you no-where fast.

IF you find your topping lift is always catching in your battens, once the mainsail is up, you can either unclip it at the boom end and temporarily clip it near the mast (ok for small boats), or you can use a light tension cord from the forward boom or gooseneck area and clip it to the topping lift just above the boom to prevent it from flying aft .. but this retainer is best set up without tension that could adversely affect sail shape.

Leech lines (down inside the rear seam) are another thing. Personally, I never tighten mine … but leave them in their sleeve just to add a little ‘body’ to the rear edge Tightening a leech line typically curls the leech to windward, forming a brake or partially stalled sail. Even if the leech is loose and flapping, that’s better than a fixed curl in my opinion. Better to think of the flapping like a sculling oar moving the air aft. Yes, a tensioned leech line will cut the noise, but it will also slow the boat.

To further keep the leech as flat as possible, I favor having multihull sails reinforced with a wide doubler in that area and always buy mine that way. As this also retards leech stretching, adding years of useful life, I find this particularly valuable for a multihull, when almost ALL the sail tension is applied down the leech from the mainsheet. No other part of a multihull main is stressed more.

So shapewise, do all you can to have the leech almost flat and when going upwind, parallel to the centerline of the boat. It may be a little freer to leeward, but never to windward, unless for some bizarre reason, you really DO want to stall the sail and seriously cut your speed.

In order to achieve adequate fullness down low with short-footed foresails, one can benefit significantly in light to medium winds by rigging a mikelin, a line that takes the horizontal sheet tension off the sailcloth at the foot. This will be fully explained in Sailing Tips Part 2.

Setting Sails

The mainsail is typically first hauled up as high as possible, or if it is a short luff storm sail, as high as is needed to lift the boom above a horizontal line to give enough clearance to duck under. Then firmly cleat the halyard. (Not wanting to have a conventional horn-cleat that can catch jib-sheets and add unnecessary air resistance, my manual for the carbon fiber wingmast includes a compact design of ‘halyard snubber’, which when combined with a cam-cleat gives secure cleating as close to the mast wall as possible – see pic).

The mainsail is typically first hauled up as high as possible, or if it is a short luff storm sail, as high as is needed to lift the boom above a horizontal line to give enough clearance to duck under. Then firmly cleat the halyard. (Not wanting to have a conventional horn-cleat that can catch jib-sheets and add unnecessary air resistance, my manual for the carbon fiber wingmast includes a compact design of ‘halyard snubber’, which when combined with a cam-cleat gives secure cleating as close to the mast wall as possible – see pic).

Now hook the Cunningham tackle into the eyelet that needs to be about 200mm above the boom and tension the luff. (If your sail does not have this eyelet, get one added, along with the necessary sailcloth reinforcement).

Except for very light wind sailing, the luff will require to be fairly tight … enough to remove any horizontal wrinkles near the luff rope plus a little more, as the wind will blow-out most small vertical wrinkles. Because of inevitable friction at the masthead sheave, it’s worth initially tightening the Cunningham really hard to get most of the stretch out of the halyard that’s ideally inside the mast. Then, the tension can be eased off a little to suit the weather – still tight in high winds but eased off a little in light weather to allow some horizontal ‘speed wrinkles'. Normally, with ‘a bendy mast’, one might adjust this Cunningham more often to suit conditions, but with a sail set behind a non-flexing wingmast, it has far less effect on the overall result, as the first 200mm of the aerofoil camber near the luff is now created ‘solid’ by the mast itself, so is automatically wrinkle free.

The final mainsail adjustment is with the outhaul. With the fully-battened W17 rig, this primarily adjusts the camber in the lower part of the sail … so needs to be set accordingly. I have found it seldom needs to be tight as the lower part of most sails are already cut rather flat … typically too flat for me. Later in this article, there is a table giving my suggested sail camber for different winds. This gives 8% camber for 25 kts which for most small boats is a STRONG wind. If the foot is 2.4m, this means a camber of 192mm, meaning that the outhaul is correct for that wind when you can push out the lowest batten nearly 200mm from the boom. But at only 5kts of wind or less … a mere zephyr, we are looking for 16% camber, or 390mm (!) of flex in the very lowest batten at the boom. As your apparent (interactive) wind may be higher than this, the camber can be reduced accordingly, but could still be more than we typically see, and I’ll stand by my recommendation until it’s proven to be too much. (Camber will need to be progressively less higher up though, as the chord will be shorter and the wind speed higher).

(Slower boats, be they multihulls or monos, will sail more often with their wind aft of the beam and in such cases, will generally benefit from the addition of a kicking-strap (also called ‘kicker’ or ‘boom-vang’) that pulls the boom down with a tackle between a point on the boom and the base of the mast to keep the mainsail leech straighter, significantly reducing rolling and improving mainsail-drive efficiency when sailing 'off the wind'. Multihulls, especially those with a wide mainsheet track like the W17 have no need of this equipment as they seldom sail with apparent wind aft of the beam, and even if they do, their mainsheet effectively does the job when combined with a wide traveler that’s used correctly).

A word about Booms

It’s been my experience that sails without booms can only be perfectly set and controlled when the clew is close to the deck and led to a point that provides adjustment both fore and aft as well as athwartship. This applies to both main and foresails. As the mainsail typically carries the most sail, a boom is essential for high efficiency in all directions, whereas one commonly accepts to compromise for foresails that are smaller. However, jibs with booms can still give that extra control and even rotating camber-booms (inside large sleeves), have shown better overall performance if you can suffer their inconvenience due to no longer being ‘roller furlable’. Mainsails without booms only work well in a close-hauled tight position and cannot be recommended for overall efficiency. Boomless mainsails put high loads on their battens when eased off, so sails can soon go out-of-shape. (Boomless sails need much heavier battens so become like multiple booms within the sail). Even for small pleasure boats, they allow far too much twist and camber, causing the boat to oscillate dangerously downwind, and to be frank, I am not convinced that a large, multi-sheave-block hanging from a clew that is now free to swing fore-and-aft as well as sideways, is any less dangerous than a boom that can more readily be grabbed to check its passage across the boat. Sorry, but for me, it’s just too much of a compromise on efficiency. Anyway, I also use my boom for other important things, such as a core for rolling up my mainsail and …. well, even for drying clothes or supporting a sun or rain cover while at anchor ;-)

Also, when releasing the mainsheet to a boomless sail in a gust, it does not fall-off as a boom does. It allows the clew to move forward, now putting more camber and power into the sail, just when you want less. Not a good solution for me.

And performance-wise, race classes that allow both boom or boomless rigs, often end up giving the boats different handicaps, as in moderate winds and above, boats with booms have typically proven to be both faster and safer.

Now to the Jib.

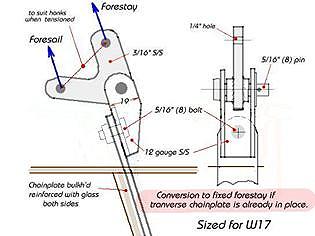

The jib luff needs to be as tight & straight as practical. If the jib luff is the forestay (as on the W17), it will basically be tensioned by the shrouds so will generally be fairly tight. It does not need to be ‘brutally’ tight’ though (as often seen on monos) as the mainsheet will add the final tension to the forestay via the mainsail leech and mast. If your jib is hanked to the forestay, the halyard will apply luff tension, but this needs to closely match the forestay tension or the latter will go slack and offer no support. While this balance can be achieved by eye for different wind conditions, a rocking equalization mount (like I first built for a racing dinghy back in 1958), better guarantees that  the jib luff and forestay share the load. See sketch.

the jib luff and forestay share the load. See sketch.

If the jib luff is long (say from the mast head), there will always be a certain ‘sag’ from the straight line. Although this is best kept to a minimum (by a stiff mast or backstays), the amount of remaining sag must be recorded and the sailmaker informed, so that this same amount is removed from the jib luff … otherwise the foresail will always be too full. This is generally more apparent with larger foresails such as a genoa.

Typically, the jib tack is lashed to the lower thimble of the forestay on the W17. With time, the sail can change a little – stretching with use, but sometimes even shrinking with age. So this lower attachment may need adjusting after a few seasons use … with the tack lashing effectively becoming a Jib Cunningham. Tensioning the luff of any sail will pull the fullness forward, but when sailing, this fullness will be moved aft by air pressure and friction over the sail surface, so keep a constant eye on your actual sail camber. While the point of maximum camber can be allowed to move to 45% back on a mainsail sailing in moderate to strong wind, it should be more forward on the jib, more like 35%. If it’s too far back, try tensioning the Cunningham. With old tired sails, it will generally mean a visit to the sail loft.

Unless there is a jib boom, the jib ‘outhaul’ is the actual jib sheet and it’s important that the sheet lead blocks are set at the right location so that tension is initially roughly equal on the leech and the foot. If not, then one can move the jib-sheet blocks or, often easier for a W17, raise or lower the jib by changing the length of the upper wire strop to the mast hound beak and adjusting the lower tack-strop to suit.

The jib sheeting must be adjustable for different conditions, so let’s consider what can be done beyond the basic sheeting adjustment. Some boats have their jib sheet leads on a track that can be moved fore & aft, or even a little inboard or outboard. Moving the lead more forward, will move the tension from the foot to the leech ... allowing more camber for lighter winds. Moving it rearward, will tension the foot but ease the leech, helping to avoid mainsail back-winding or spilling excess wind in heavy conditions.

But the W17 system is simpler and lighter with no tracks required. First, after the leeward sheet is set, the normally idle weather sheet can be slightly tensioned to pull the jib clew closer to the mast for a finer sheeting angle … even down to 10 deg can be useful on some close-winded boats.

(A supplementary line that adds side tension to change the load direction of the primary one is generally called ‘a Barber Hauler’, so in this case, the weather sheet is being used as a Barber Hauler).

Also, as the W17 sheet has 2-parts, the standing part can be pulled down under a small hook mounted about 200-250 mm forward of the normally attached position (see above photo of jib sheet). This will add tension to the leech without adding as much to the foot … so permitting a little more camber in the sail for lighter winds. Using the ‘telltales’ will help to guide the ideal sheeting … something that will be discussed in Part 3.

But now, what if the wind is very light … say under 5kts and we are looking for that 16% camber?

We can achieve more camber if we just slacken off the jib sheets completely, but then the leech is also slack and the sheeting angle is so large that there’s no upwind drive or ‘slot-effect’ with the main. So what to do?

This is where a mikelin can really help. There will be more on this in Part 2, but basically, it is a horizontal line that is added to take the foot tension of the foresail. (See Part 2 for photos & more explanation).

Boat Trim

Take note that small boats of all types, particularly those under 6m (20ft), will need to use the movable weight of crew members to constantly modify the heel and trim in order to sail at the highest efficiency.

First and foremost for a trimaran, it’s important to never sail the boat on three hulls! When sailed very light, a few trimarans with high amas (high dihedral for the aka beams) can actually be balanced just on the central hull with the amas clear of the water. This is faster in light wind and my old Buccaneer was like this. However, the high dihedral meant the boat heeled a lot more to find its float stability so losing valuable sail drive, even if offering a boat-rig that spilled wind gusts more automatically. (High dihedral also makes a boat very skittish and ‘flip-flop’ at anchor). Later designed boats generally avoid this, but require that the movable weight (crew) is always conscious of the heel and ready to move from windward to leeward should the wind not be enough to get the windward ama (float) out of the water. At the same time, the crew should be ready to move back to windward if they see a darkening of the water to windward, indicating an imminent wind gust. Ideally, the windward ama should be just above the water surface and if the ama bottom shape is correctly engineered, clipping a few wave tops will be silent and smooth, so of little concern. But if your windward ama annoyingly slaps, you may need to heel your boat more to gain clearance. Although the helmsman might help with this adjustment of heel, the main weight movement should be one of the principal duties of the crew when there is one.

Fore and aft trim is equally important for best performance. When sailing upwind, one needs to trim forward to keep the narrow bow as deep as practical*, with the leeward aft chine (on a W17) exiting the water close to the transom. This will not only give the longest waterline length, but also give the minimum wetted surface and related skin friction. When sailing alone in light weather, I often sit tight to the forward beam on my W17, using a long, lightweight tiller extension of PVC ... (see photo).

Fore and aft trim is equally important for best performance. When sailing upwind, one needs to trim forward to keep the narrow bow as deep as practical*, with the leeward aft chine (on a W17) exiting the water close to the transom. This will not only give the longest waterline length, but also give the minimum wetted surface and related skin friction. When sailing alone in light weather, I often sit tight to the forward beam on my W17, using a long, lightweight tiller extension of PVC ... (see photo).

NOTE: The asterisk against the words ‘deep as practical*’ needs clarifying. When sailing in steep waves that are very close (as often found on a large and windy lake) ... the practical limit can be exceeded when wave tops start to come over the foredeck …. so a balance will be required between good bow depth and required forward freeboard. Allow me to also diverse here and get a certain message across. This is a point I like to emphasize, both when sailing and designing.

A boat is required to be supported by upward forces that match its weight. IF going fast enough, some of that can come from dynamic lift, as offered by planing surfaces or foils. However, most of the time, its weight is supported purely by hull buoyancy, so now it’s for the designer AND later, the sailor, to decide just where is the best location for that buoyancy to give the least resistance to forward motion ? If there is little chance for dynamic lift, I have observed that getting more buoyancy up forward will lower forward resistance, especially if added deep below the waterline and not at the surface. So either the designer can work this into his design, or the sailor can move forward to achieve something similar, keeping in mind that every cubic centimeter added forward (where the waterline is narrow) will be a cubic centimeter less to support aft where the boat is generally much wider. If the designer and sailor work together on this, the improved results are significant. But with any design that’s light enough to be heeled and trimmed with manpower, the sailor needs to decide where best to get his buoyancy from, and then adjust crew positions to suit. The gains are measurable.

As you bear-off to sail on more of a reach, your weight can slowly slide aft, but only when the wind is moderate or strong. As you move to a broader reach, say 45 degrees from a true downwind run, then in moderate to strong winds, you will need to slide your weight (as well as that of the crew), farther aft. The stronger the wind, the farther aft you need to go … even ending up sitting on the aft beam of a multihull. This can bring its own adventure. (I was sitting on the rear beam of my W17R one day when a strong gust hit. The sudden acceleration had my feet rising off the trampoline and for a second I thought I was going off the back! IF that ever happens to you, do NOT let go the tiller extension … another good reason for a long, flexible one of PVC. The pull on the extension will turn and slow the boat, giving you the best chance to get back on board. But the experience has me making a couple of lightweight backrests of PVC tubing and carbon fiber sockets that will make ‘the back roll’ far less likely. Options are to add a line from the forward beam with a loop you can hold on to, or … just don’t sit up there! Such acceleration is what you get to enjoy with high stability and a powerful rig ;)

As you bear-off to sail on more of a reach, your weight can slowly slide aft, but only when the wind is moderate or strong. As you move to a broader reach, say 45 degrees from a true downwind run, then in moderate to strong winds, you will need to slide your weight (as well as that of the crew), farther aft. The stronger the wind, the farther aft you need to go … even ending up sitting on the aft beam of a multihull. This can bring its own adventure. (I was sitting on the rear beam of my W17R one day when a strong gust hit. The sudden acceleration had my feet rising off the trampoline and for a second I thought I was going off the back! IF that ever happens to you, do NOT let go the tiller extension … another good reason for a long, flexible one of PVC. The pull on the extension will turn and slow the boat, giving you the best chance to get back on board. But the experience has me making a couple of lightweight backrests of PVC tubing and carbon fiber sockets that will make ‘the back roll’ far less likely. Options are to add a line from the forward beam with a loop you can hold on to, or … just don’t sit up there! Such acceleration is what you get to enjoy with high stability and a powerful rig ;)

Sail Trim

When sailing upwind, thrust is created by gently deflecting the air over a slightly curved surface of the sail and accelerating the retained air flow off the leech. But it needs to be gently corralled into the sail and held close to it without separation that would cause eddies and drag, so at the entry (luff), the wingmast and sail is pointing almost directly into the apparent wind. From this point, sail curvature will start to perform its magic. Test have shown that, IF the air flow can follow the foil surface, a camber of 1/6th the chord creates a very effective thrust, but this is too much for higher air speeds as the air breaks away from the surface. 1/10th or even less camber is then required (see table below),

One way to think about this is to consider that the forward driving force is a product of camber x air speed – but only UP TO the point that the air flow can stay on the sail surface. High air speed will require LESS camber to achieve this. From my own observations, here are some suggested sail camber values as needed to match the apparent wind.

Pressure on sails (lbs/sqft = 0.0012 x C x v2) [v = ft/sec C=1.2 or if in knots, P ~= 0.004 x V2

Apparent Wind (kts) 5 10 15 20 25 30 35 40

Suggested Sail Camber %: 16 14 12 10 08 06 04 02

or: Chord/Camber Ratio (C/C) 6.2 7.1 8.3 10 12.5 16.7 25 50

Pressure (@C = 1.2) lbs/sqft 0.1 0.4 0.9 1.6 2.5 3.6 4.9 6.4

How wind force is applied to the boat will depend in good part on the angle the leech area makes relative to the boat. This in turn will depend on the mainsheet tension and how effectively it is sheeted. As the sail is let out for reaching, a wide mainsheet track can keep the leech area flatter for more effective drive. Without a wide track one can lose some of that, as one will see the boom lift up, allowing the leech to spill air off to leeward instead of driving the boat forward. (Typically, boats with narrower mainsheet sheeting, must add a boom vang to apply the necessary down-force on the boom to keep the leech flat).

Once again, the leech ‘tell-tale’ can add a visual factor to the air flow … see Part 3.

Sailing Downwind

Typically, multihulls are almost never sailed directly downwind, but on the W17 I’ve observed that with sails winged out to each side, the speed in medium winds is ‘pretty good’, so only by racing identical boats against each other can one really see if it’s still slower than the more generally acknowledged tacking-down-wind with multiple gybes. Meanwhile though, here’s a rough guide.

To tack downwind at an assumed 35 degrees off the straight downwind line on each gybe, you will need to travel approximately 22% faster to cover the extra distance. (Or approx. 42% faster average if at 45 degrees off-wind, and that means making 8.5kts instead of 6). Significant differences ... but sometimes feasible.

Although personally, on my W17 in moderate wind (say 5 to 8 kts), I’ve found it quite efficient to go ‘wing-on-wing’ straight downwind as noted above, in both lighter and heavier winds I found tacking downwind does work best. In the case of very light winds, it helps to create a higher apparent wind to keep you moving (say at 140/220 deg), while in heavier winds, it gives you the ability to steer up and over waves to lower the risk of sticking the bow under, (something that can happen if you go straight downwind at high speed), as well as enable sailing in the fastest water of a wave, something I will discuss more in Part 4 of this series.

============================================================

Continued in Parts 2, 3 & 4 that address :

Part 2: Tacking, Sail Camber, Wing Masts & more

Part 3: Tell-Tales, Airflow and related efficiencies

Part 4: Sailing Downwind and In Waves

(Your comments, personal tips and questions are always welcome ..

"New articles, comments and references will be added periodically as new questions are answered and other info comes in relative to this subject, so you're invited to revisit and participate." —webmaster