.

A Postmortem on “the Flight of Magic”

Well, for September 2022 I had hoped to be writing about Camp Cruising on a W17, but nature has a way of changing plans at the last moment. I thought I had seen about everything re small boat adventures, but even though I have seen this once before with a 23ft Stiletto catamaran that broke in half after its ‘flight’, I certainly never expected anything close would happen to me.

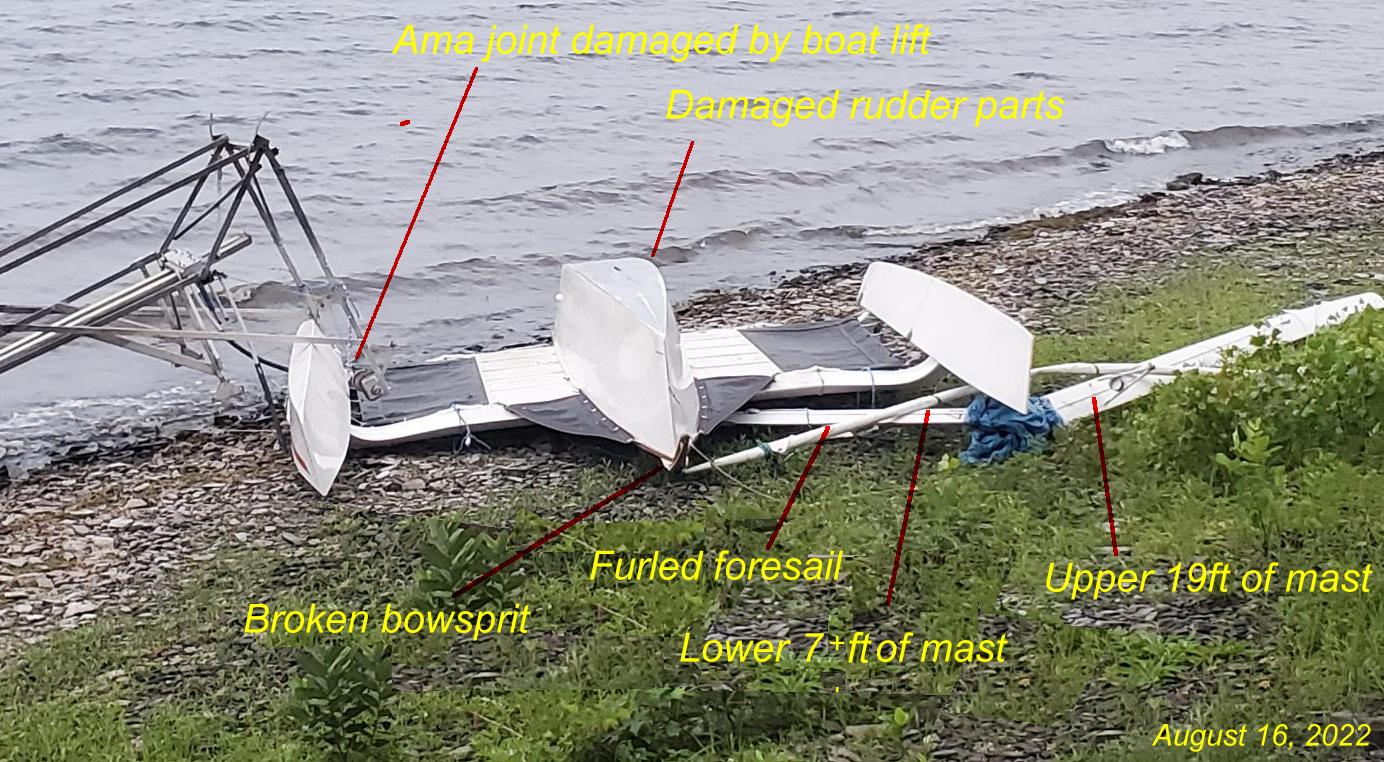

But on Aug 16th [2022], a very vicious micro-burst brought a high powered wind (reported as ‘something over 60 mph’) for just a few minutes, but in that short time, totally picked up my trimaran ‘Magic’ from her boat lift and literally ‘flew her through the air’ while turning, to land about 15ft up my stony beach, pancaked upside down !

Although I was quite devastated for the first 24 hours, thinking, “is this really the end of my sailing days?”… knowing I am no longer able to see well enough to build another W17. So for those initial hours, I could not even bring myself to look at her closely so just assumed the worst from the little I could see.

Although I was quite devastated for the first 24 hours, thinking, “is this really the end of my sailing days?”… knowing I am no longer able to see well enough to build another W17. So for those initial hours, I could not even bring myself to look at her closely so just assumed the worst from the little I could see.

But over the next few days, I started to examine her closely and I was quite encouraged by the little real damage she suffered. Quite remarkable actually. While I do not wish such ‘a lesson’ on anyone, when it happens there are important things we can learn, so this article will take you through what probably happened, to discuss what worked out ok and why.

Although there were perhaps a dozen smallish knocks from hitting a small rock when landing, there was only one place where the plywood was slightly damaged and that was on the beam fairing that is not structural. So how did this 420 lb boat fall from at least 8ft if not significantly more, and not be more banged up? The answer lay in good construction and materials, a structural design (ABS System) that reduces local hard spots, and certain sacrificial parts.

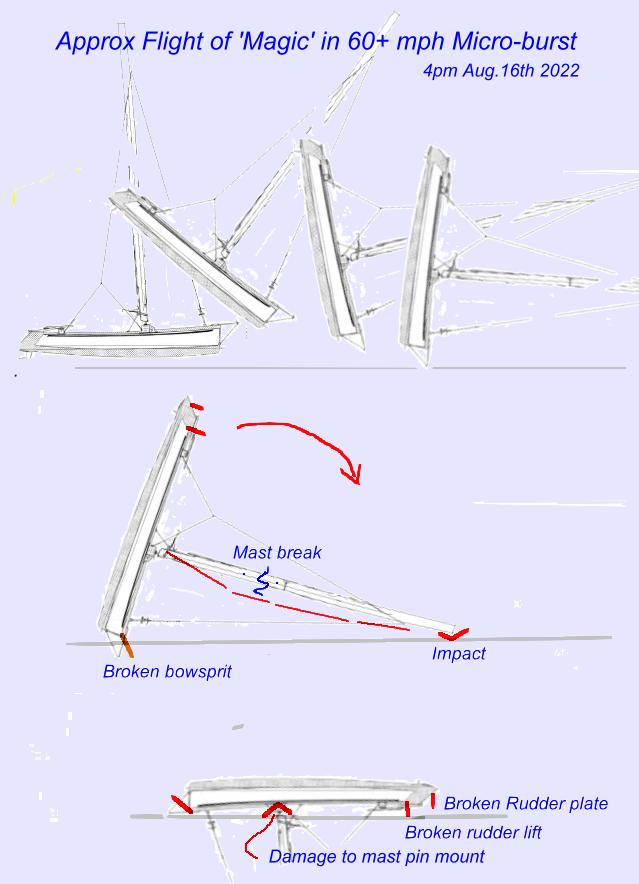

The first ‘touch-down’ was the laminated bowsprit.  Although of mahogany on the outside (for sideway strength), the core is cedar, so when the tip was violently pushed down, the core was penetrated by the strong vertical stem and mahogany gunwale of the main hull and led to its failure. It could not stop the boat rotating but it most likely slowed it down. The next contact was most likely the mast tip. Having the 8m carbon fiber wingmast that is very strong, the tip dug into the beach (with only a paint scar) and slowed the boat right down so that it then collapsed more vertically over the mast. Despite its great strength, the mast is not designed to have 420 lbs thrown at it sideways and either snapped when the boat actually landed or possibly even before. Note the word ‘snapped’. If this were an aluminum mast, it would first have bent and then buckled. If the bend goes much beyond the elastic limit of the aluminum, which it commonly does, then the mast ‘is toast’, unfixable.

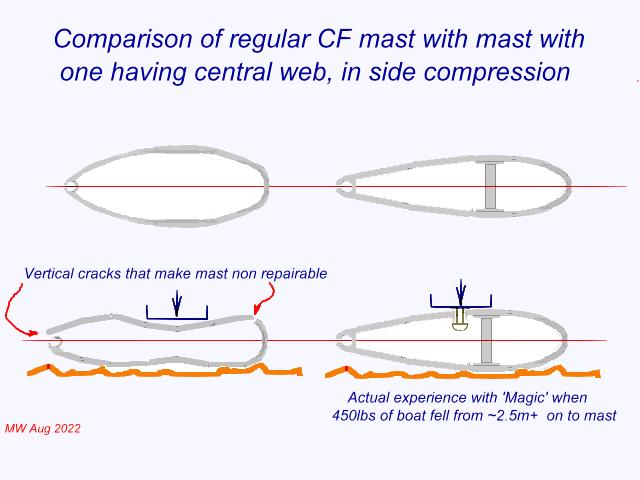

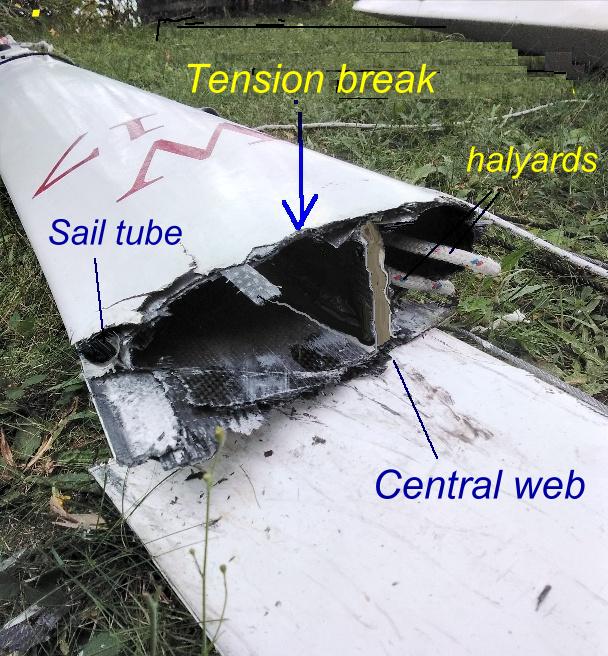

Although of mahogany on the outside (for sideway strength), the core is cedar, so when the tip was violently pushed down, the core was penetrated by the strong vertical stem and mahogany gunwale of the main hull and led to its failure. It could not stop the boat rotating but it most likely slowed it down. The next contact was most likely the mast tip. Having the 8m carbon fiber wingmast that is very strong, the tip dug into the beach (with only a paint scar) and slowed the boat right down so that it then collapsed more vertically over the mast. Despite its great strength, the mast is not designed to have 420 lbs thrown at it sideways and either snapped when the boat actually landed or possibly even before. Note the word ‘snapped’. If this were an aluminum mast, it would first have bent and then buckled. If the bend goes much beyond the elastic limit of the aluminum, which it commonly does, then the mast ‘is toast’, unfixable.  One great thing is that when CF ‘snaps’, there is rarely any deformation to the adjacent section or material. However, if we look at a regular CF mast without an inside web (see sketch), it’s all too easy to flatten the section that will then crack vertically down the front and rear edges as there is not much material there to resist such a force as most of the fibers are running up and down (unidirectional), so once again, such a mast would be scrap with no practical way of repairing it. It’s only by the internal web maintaining the sectional shape that such a mast can be salvaged. Pro-built CF masts are typically made ‘from the outside in’, laying them up inside a female mould and then bonding together the two halves. But the Waters Wingmast reverses this as it’s built ‘from the inside out’. This permits the inner structure to be recreated over the fractured area and then the outside strength ‘layered on’ just as the mast was initially built, enabling such a mast to be uniquely repairable. How this is done in detail, will be the subject of another article once the job is done, but ‘the operation procedure’ is now being developed.

One great thing is that when CF ‘snaps’, there is rarely any deformation to the adjacent section or material. However, if we look at a regular CF mast without an inside web (see sketch), it’s all too easy to flatten the section that will then crack vertically down the front and rear edges as there is not much material there to resist such a force as most of the fibers are running up and down (unidirectional), so once again, such a mast would be scrap with no practical way of repairing it. It’s only by the internal web maintaining the sectional shape that such a mast can be salvaged. Pro-built CF masts are typically made ‘from the outside in’, laying them up inside a female mould and then bonding together the two halves. But the Waters Wingmast reverses this as it’s built ‘from the inside out’. This permits the inner structure to be recreated over the fractured area and then the outside strength ‘layered on’ just as the mast was initially built, enabling such a mast to be uniquely repairable. How this is done in detail, will be the subject of another article once the job is done, but ‘the operation procedure’ is now being developed.

It’s possible that the spreader was pulled off the mast, so that the whole mast was then like an unsupported 8m beam, snapping close to where the main beam rises to its highest. But even with the boat falling on the side of the mast, the section did not collapse, so as noted above, there was zero failure of the section from the boat actually squashing it. The lower part was trapped under the falling boat and the ‘now free’ 5/8” dia. S/S pivot bolt punched a neat hole through the side wall of the mast, but the section still did not collapse due to the central web that stayed intact. The upper mast was clear of the boat, so only the spreaders broke off with no other damage. Again, a simple pinned connection for the spreaders enabled them to break free of the mast, without damage to the mast structure itself. That is something important to maintain. Designing or building over-strength connections can sometimes prove to be more damaging and even weaker than having ‘the right engineered balance’

It’s possible that the spreader was pulled off the mast, so that the whole mast was then like an unsupported 8m beam, snapping close to where the main beam rises to its highest. But even with the boat falling on the side of the mast, the section did not collapse, so as noted above, there was zero failure of the section from the boat actually squashing it. The lower part was trapped under the falling boat and the ‘now free’ 5/8” dia. S/S pivot bolt punched a neat hole through the side wall of the mast, but the section still did not collapse due to the central web that stayed intact. The upper mast was clear of the boat, so only the spreaders broke off with no other damage. Again, a simple pinned connection for the spreaders enabled them to break free of the mast, without damage to the mast structure itself. That is something important to maintain. Designing or building over-strength connections can sometimes prove to be more damaging and even weaker than having ‘the right engineered balance’

I will get back to the mast in a moment, but let’s ‘fully land the boat first’ ;)

As the stern dropped, the lowest point became the two vertical projections from the rudder, as the rudder was UP in the moored location. One was the arm that helps to lift the rudder up when going ashore or moored. The other projection is the plywood closing plate that normally closes the V-gap aft of the transom. In the final seconds of the fall, this also served as a brake but at some point caught something solid, stopped the boat but was snapped off while doing so. This plate normally takes only a low side loading and as there is no other sailing force on this plate at all, it was easy to re-attach it to become fully effective again, using the Vee in the boats’ bottom to get perfect alignment.

So, having sacrificial parts that are easy to fix or replace, has good engineering reasons to not be overbuilt. For example, if the rudder plate was thicker and had not broken, the load would have ripped the alum pivot hinge apart, but there was zero damage to this. Also, with the boat now upside down, the mast pivot pin (a sturdy 5/8” S/S bolt) would have ripped the top of the main beam off, but as it’s only attached with six ¾”screws, they just pulled out of the 6mm ply and cedar block on which it normally rests .. and the main beam stayed 100% intact and undamaged. Because the load on this pin is normally 95% vertical, those 6 screws are perf ectly adequate for the mounting and served a sacrificial role when the worse occurs.

ectly adequate for the mounting and served a sacrificial role when the worse occurs.

The final ‘shot by fate’ on ‘Magic’ was surprisingly made by the boat lift. As once previously, high waves had floated the boat off the lift to end up on the shore 1/4mile away, (again nothing more than paint damage occurred due to the use of Kevlar on her chines and bottom), I had got in the habit of lashing the boat to the lift once in place. But now, with the boat flying ‘head over heels’ out of the boat lift, the boat ended up pulling the boat lift over and after the boat came to rest upside down, the final card played by nature was for the metal lift to fall down on the rear of the nearest ama like an axe blow .. but as the slope of the ama side happened to exactly match the angle of the lift (see photo), the chopping blow did not do any vertical damage, but it did wedge the ama horizontally away from the aka. Again, there is normally very little force ever doing this while sailing, but this was a freak blow. The 20 sq.in connection failed when the 8mm plywood deck-pad failed in shear, but was very easy to re-bond back in place. Of course, it never came completely apart as the 8mm through-bolt was still very much intact, proving it’s still a good idea to have them ! With the reinforced epoxy (used for rebonding) being stronger than the original plywood, the joint will be better than new.

|

Since making the above ‘flight sketch’, I realized that the boat did not complete a full pitchpole but must have done a ‘barrel roll’ In the air, as finally, the bow was turned only 90 degrees from its original direction on its boatlift.

Rewardingly, NO damage was done to any of the hinges or latches and neither with their connection to the akas, so anyone with concerns about their strength can now sleep soundly … the akas and amas survived totally intact with hardly a scratch. And after inspecting the inside of an ama with an Infra-Red camera probe, I also found zero issues visible inside. (Although inside work to an ama (or even under the cockpit floor) would mean making a hole in the deck for access, this is still totally doable and quite practical if ever needed).

While the dozen or so small things that needed fixing involved a little work, the big challenge has to be the mast. Looks pretty sad like this ;)

We often hear that most broken masts cannot be fixed but the impossibility of me making a new one at my age, gave me a good push to figure a way to repair this one. [Work was underway when first writing this, but see below for latest status].

‘Magic’ WILL of course sail again as only the mast issue is serious … and the main thing, no one was hurt. Such a boat of ‘400lb plus’ was noted by the friends who came to help, to have other advantages. By simply pulling the hinge and latch bolts, it was easy to slide away the amas and at 90lbs each complete with their curved akas, were each an easy lift and soon stored away. In less than an hour, the main hull was stripped of gear, (anchor, chain, warp, boom, sails, rudder, mast and rigging etc)_ and 2 people could then readily roll the hull over sideways on to a rubber mat, so making the beams a good height for 4 persons to walk the 200+lb main hull to wherever it needed to be. In my case, once up the right way, we floated the main hull on to a floating trough that has 8 wheels under it. This works as 'a marine railway’ and we could easily push the boat and ‘her drydock’ up the beach to a ramp where a winch took over to crank it 6ft higher where her inspection and repair work could be undertaken.

Thankfully, I still enjoy ‘m essing around with boats’, so most of this is still quite interesting and enjoyable. What I WILL need for the future, is some way to hold the boat down to prevent a repeat of such a thing and I am considering a very heavy anchor and chain laid some distance upwind, with a line I can clip to the boat or a halyard, so that the boat cannot be lifted or ‘capsized’ again. Putting her on a mooring would be another solution but I hesitate here, as compared to a boat dry-sailed, a moored plywood boat seldom has quite the same life without LOTS of maintenance, freshwater rinsing and constant drying out. Adding a short stern line to a very heavy weight or anchor (100lbs +) might do it as also would using ‘the rolling dry-dock’ each time and leaving it on the beach (when the water has receded enough for it to be there!

essing around with boats’, so most of this is still quite interesting and enjoyable. What I WILL need for the future, is some way to hold the boat down to prevent a repeat of such a thing and I am considering a very heavy anchor and chain laid some distance upwind, with a line I can clip to the boat or a halyard, so that the boat cannot be lifted or ‘capsized’ again. Putting her on a mooring would be another solution but I hesitate here, as compared to a boat dry-sailed, a moored plywood boat seldom has quite the same life without LOTS of maintenance, freshwater rinsing and constant drying out. Adding a short stern line to a very heavy weight or anchor (100lbs +) might do it as also would using ‘the rolling dry-dock’ each time and leaving it on the beach (when the water has receded enough for it to be there!

Mike, September 2022

PS: Dec/Jan 2023 A fully detailed report on how the mast was repaired, is now available here.

"See the Copyright Information & Legal Disclaimer page for copyright info and use of ANY part of this text or article"