.

How to build an effective soft-riding trailer for a light wood boat

Many years ago now, I mentioned a trailer design I had first developed back in 1964 that used a very supple (gentle) suspension system, ideally suited for plywood boats up to about 300 lbs. The typical steel utility trailer is designed for 1100lbs (500kg) or more, and is brutally hard on a light boat as there is effectively no suspension at all ! Removing a spring leaf helps a little, but for a really light boat, this will still not compare to the trailer design detailed below.

In my 2010 article I had mentioned this :

"For light. wood sailboats (18 ft and under), I developed a suspension system to give a superior ride. I call it the ATL System, for Adjustable Trailing Leaf.

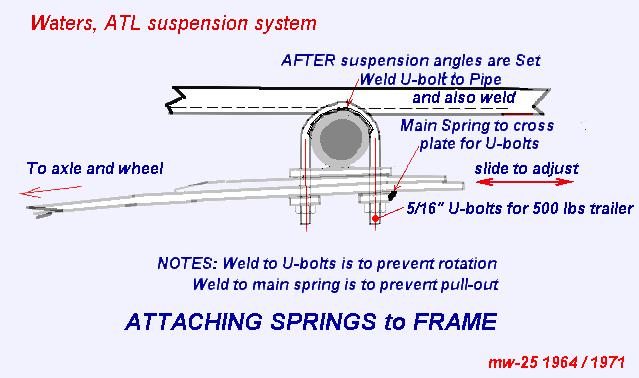

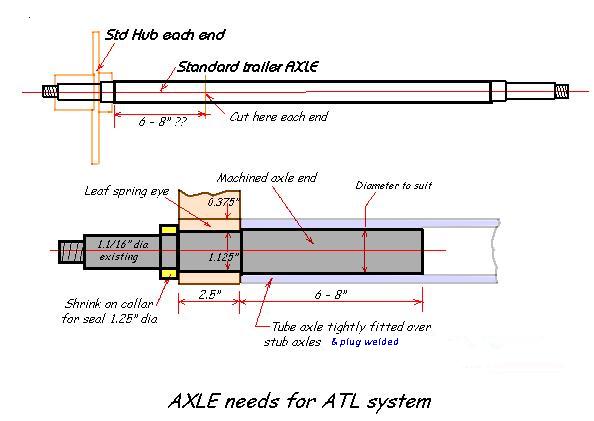

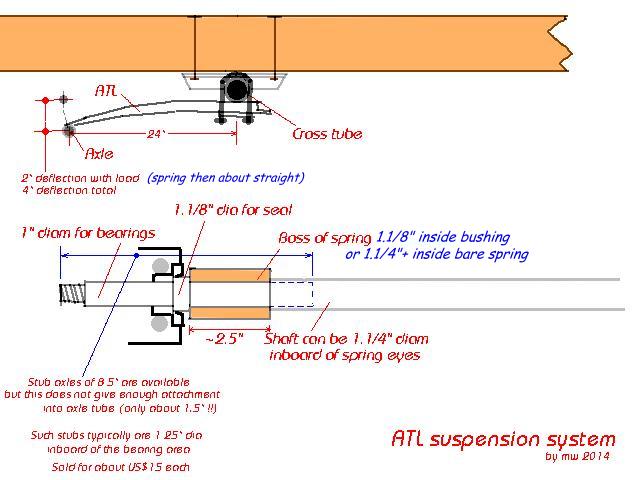

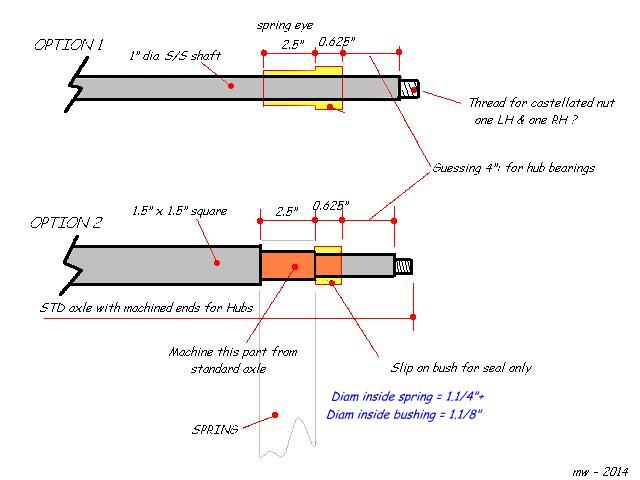

At the local scrap yard, I found the longest leaf spring that I could (40-50" long) with eyes of at least 1" diameter and had it burnt exactly in half. I also dig or burn out the old rubber bushings as I don't need them with this ATL System. I'd use a truck spring (F-150 etc) for heavier loads, or a long car spring for dinghies of 200 lbs or less. I then used each half as ‘a trailing cantilever spring’ and the fun part was that I was able to slide and remove spring leaves to get exactly the suspension height and load-carrying that I wanted. Once adjusted, I'd get the retaining U-bolts welded to the cross tube and the main trailing spring welded to the U-bolt plate, so that it could not pull out. A solid axle, machined for a snug fit within the spring eyes, worked great as an anti-roll bar and no other suspension damping was found necessary. This set up would roll sweetly at any legal speed"

So, now forward to Feb 2023. As I have had a few enquiries about building one’s own trailer of late, I thought it was time to add some sketches to fill in and further clarify the above brief description.

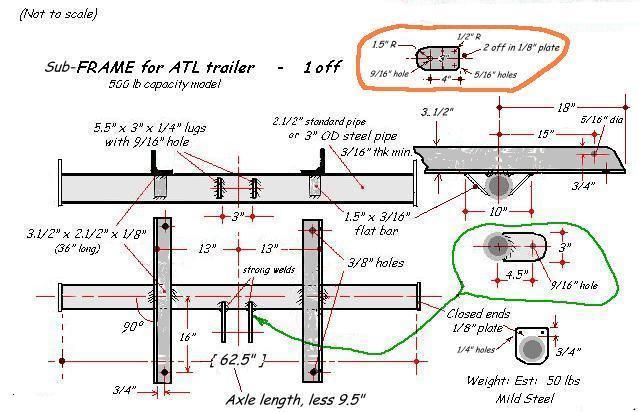

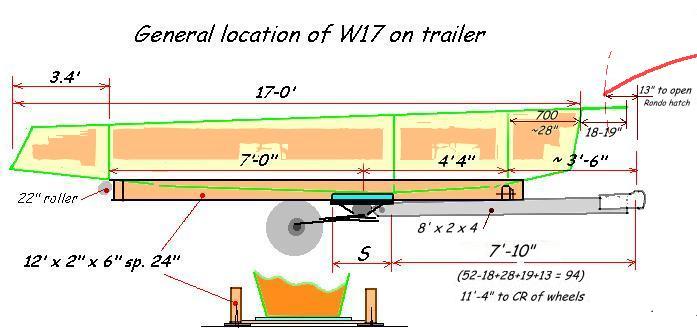

Here are some sketches dealing mostly with just the suspension part. The boat frame itself that can attach to the cross tube by welded on 3ft lengths of angle bar, is typically just a horizontal flat-bed one of wood using selected, good quality 2” x 4” (50x100) to create a frame of 48.5” (1.23m) wide and 8ft (2.44m) long, so that plywood sheets can also be transported on it when needed. Unless it will be a dedicated boat trailere, any additional boat supports required above the frame should be bolted on using wing nuts, so that they can be easily and quickly removed if you want maximum utility from the trailer. Extensions for longer boats are easily bolted on and this article already covers that for a W17 trailer. Wood frames only supporting a boat front and rear and over 3 metres long, will probably need to be made of 2" x 6" (50 x150).

.

Because the two springs are compliant and independent, some form of anti-roll bar is required. This is achieved very effectively by passing the axle through the spring eyes, thereby serving double-duty. By machining or grinding the axle ends to be a shrink fit (installing a cold axle through a heated spring eye), this forces the 1"-plus axle to link the two sides. To be totally independent, the axle would have to deform into an 'S' shape, which of course, the axle resists. But there remains enough movement for a little independence and the result is a controlled and quite 'heavenly ride'. I could trail my first of three trailers using this design (with an 11ft Moth on it) at quite high speed when needed without knowing it was there. .. no sway, no noise, no surging, no bumps. The trailing action allows the wheel to 'give' a little on impact and that really softens the road interface. The sub-frame shown here, shows a dedicated frame for a W17 with the support angle bars fairly close in as the main hull is narrow (see also sketch at bottom left). But for a 4ft x 8ft trailer, those angle supports would be 48.5" apart. The axle can be of various forms, from round bar, square bar with machined ends (a standard), or using standard round stub axles welded into a sturdy connecting tube.

.

.

.

.

.

I typically 'tune' the suspension rate to give 1” to 1.25" drop with 150 lbs (~70kg) on one side, which is WAY more compliant than most small trailers.

Note: Because the above sketches were made for different sized ATL trailers, there may be a few inconsistencies, but they will give you the principle elements to guide your own detail ATL design.

mike/ 2023

========================================================================================

.

.

"New articles, comments and references will be added periodically as new questions are answered and other info comes in relative to this subject, so you're invited to revisit and participate." —webmaster

"See the Copyright Information & Legal Disclaimer page for copyright info and use of ANY part of this text or article"