Trailer conversion for the W17 .... and flat bottoms

QUESTION: One thing that now attracts me to the W17 is its flat bottom, especially since I’ve finally understand how efficient it can be by bringing the displacement down low, which in turn reduces the side flare that disturbs the water surface more than needed. But that was the last thing I learned. The more obvious part was the easy beach-ability with simple rollers under the flat bottom and then the fact that it would sit nice and easy on either mud flats or on a flat utility trailer that can still be used for other tasks such as hauling wood, tools, plywood, furniture, bikes, skidoos or whatever. Love it ... but this leads to my question.

As regular inexpensive utility trailers typically have an 8ft long carrying frame, how do we need to modify the trailer in order to carry a boat that is 17ft long ? Advice most appreciated. JW… Quebec, Canada

.

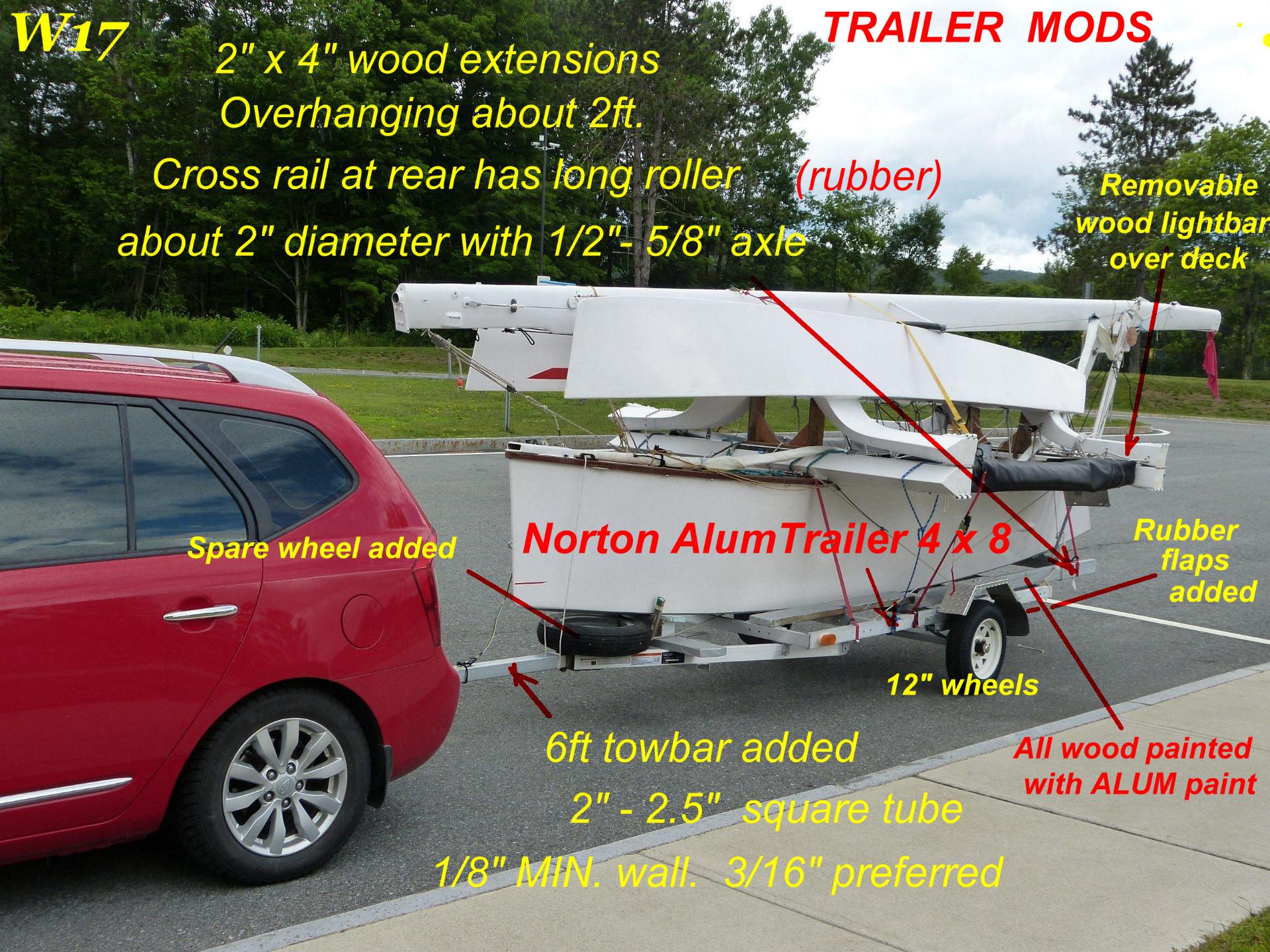

ANSWER: Thanks Jay. Several have asked this so here goes. First, there are two utility trailer widths available, 4ft and 5ft, and either of these work for the W17. The most stable is the 5ft model, as the wheelbase is wider and so is the frame to which the boat will be lashed. As the main hull bottom is relatively narrow compared to the boats beam, one needs to have tie-downs from the deck or cockpit side to the outside trailer rail to prevent a brutal capsize on land .. and the wide trailer will be even more effective for this.  The negatives are that 1) the trailer takes more space to ‘park’ when not in use, 2) is more expensive, and 3) it’s heavier. Because I am not so young anymore, I wanted the lightest trailer to handle ashore, so I personally bought a 4ft wide unit in aluminum, on special from Northern Tool (USA) for about US$500 (2016) but I see they are now $640 (2021) and the 5ft width is $800 (all with delivery included) … still a steal compared a dedicated aluminum boat trailer that’s typically 50-90% more.

The negatives are that 1) the trailer takes more space to ‘park’ when not in use, 2) is more expensive, and 3) it’s heavier. Because I am not so young anymore, I wanted the lightest trailer to handle ashore, so I personally bought a 4ft wide unit in aluminum, on special from Northern Tool (USA) for about US$500 (2016) but I see they are now $640 (2021) and the 5ft width is $800 (all with delivery included) … still a steal compared a dedicated aluminum boat trailer that’s typically 50-90% more.

Whether you lay a plywood over the frame is your choice, but I just wrapped the cross beams in the center with heavy carpet offcuts and duct taped this in place. Plywood works ok but as it does block visual access to the underside, I suggest to just use a 4-bolt (easily removable) drop-on plywood for utility trailer use.

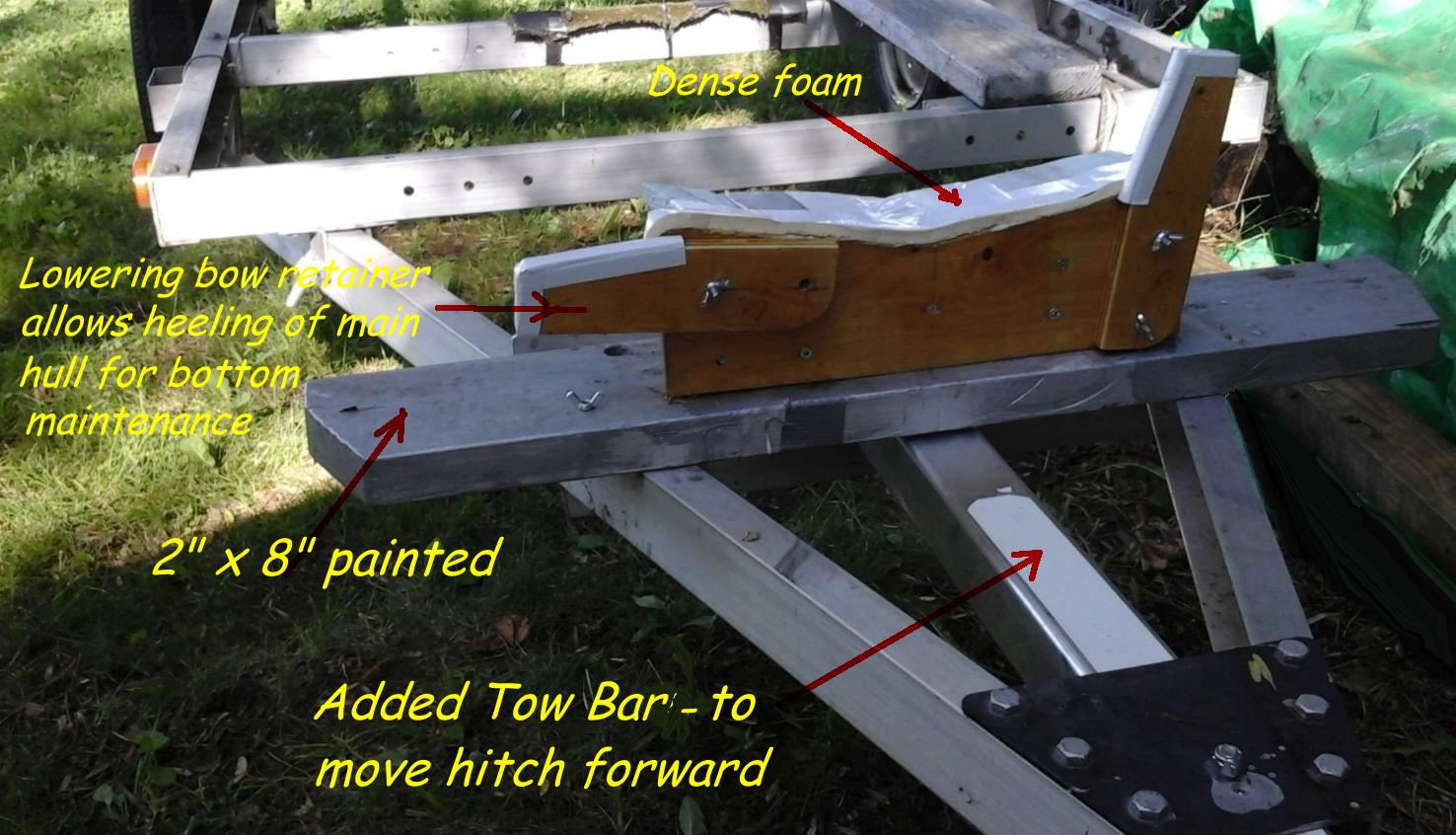

To lengthen the trailer, you need to add a tow-bar to the front, so that the hitch to wheel axle distance is about 9.5ft. I used an alum square tube of about 6ft in length, passing it through the apex of the front A-frame and back to a 2”x2”x1/4” aluminum crossbeam \angle-bar, which I added using 5/16” bolts. The tow-bar is also through-bolted at the A-frame apex with a single 3/8" bolt.

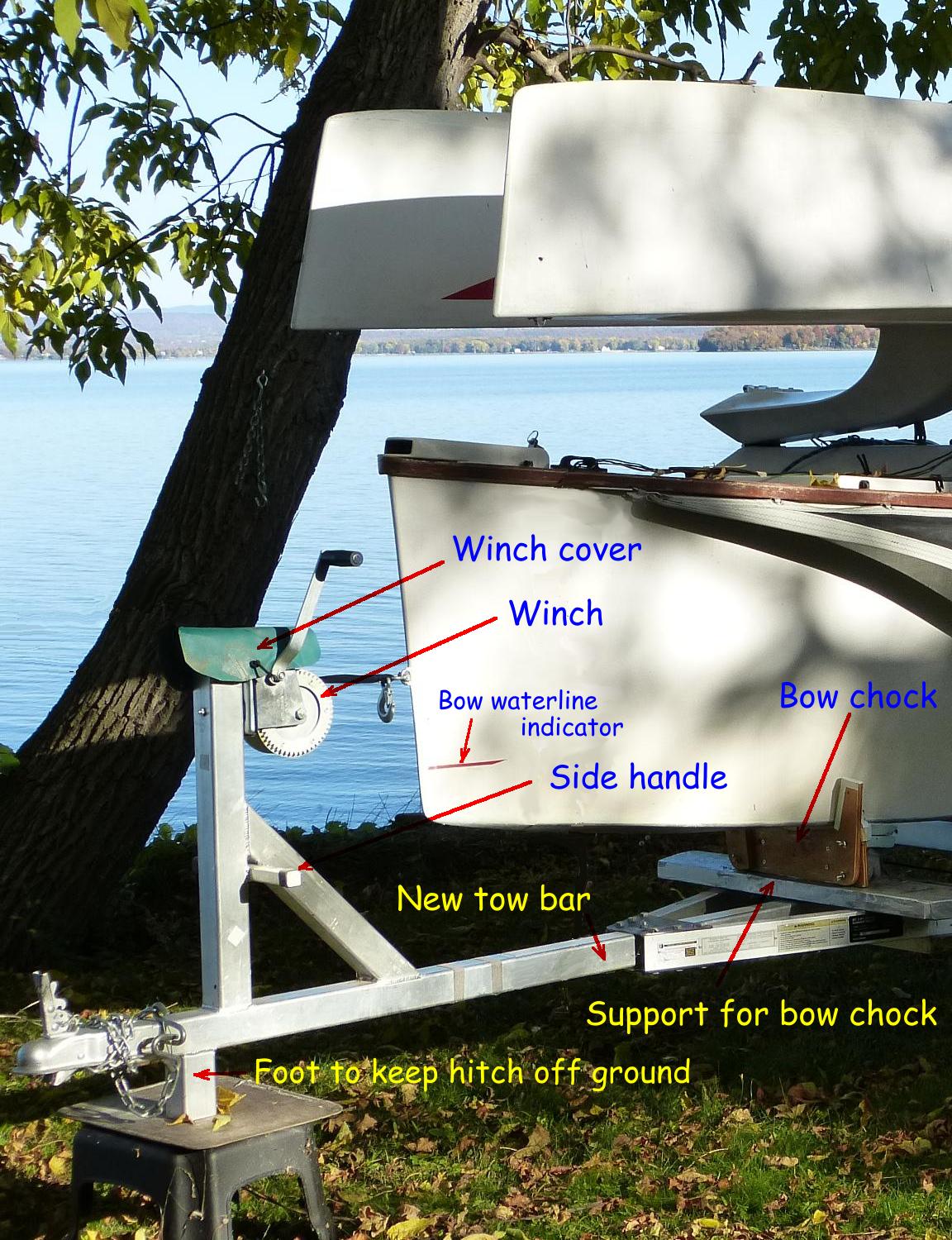

The original utility trailer has an 8ft long frame plus an A-frame of nearly 4ft at the front, so is 12ft overall. The new tow-bar will add about 3ft up front, but at the rear, another 2ft extension is needed, giving about 17ft overall. As the bow is back from the winch, the extra boat length overhangs at the rear. (added 23-03-2021 for further clarity: the photo at the right, shows the 3ft** or so forward extension from the original A-frame and also, that the new tow bar is inserted flush with the A-frame sides, with the original steel gusset plates top and bottom. Depending on its length, the rear end of the new tow bar, can finish on a transverse angle bar bolted across the A-frame - it does not really need to reach the 8ft frame. The original raised box for the hitch can be sawn off. ** the final extension length will depend on whether you install a winch or not and how large it is. see photo).

The original utility trailer has an 8ft long frame plus an A-frame of nearly 4ft at the front, so is 12ft overall. The new tow-bar will add about 3ft up front, but at the rear, another 2ft extension is needed, giving about 17ft overall. As the bow is back from the winch, the extra boat length overhangs at the rear. (added 23-03-2021 for further clarity: the photo at the right, shows the 3ft** or so forward extension from the original A-frame and also, that the new tow bar is inserted flush with the A-frame sides, with the original steel gusset plates top and bottom. Depending on its length, the rear end of the new tow bar, can finish on a transverse angle bar bolted across the A-frame - it does not really need to reach the 8ft frame. The original raised box for the hitch can be sawn off. ** the final extension length will depend on whether you install a winch or not and how large it is. see photo).

Welded above the tow bar, is an optional post for a winch. This can be used both for hauling up the boat (although I prefer to almost float it on), as well as for raising the mast. In passing, it’s worth noting that although the winch speeds up this job, you can also raise the mast with a 4-part tackle from the end of the bowsprit … this way, you can raise and lower the mast from say a beach, without absolutely needing the trailer and winch.

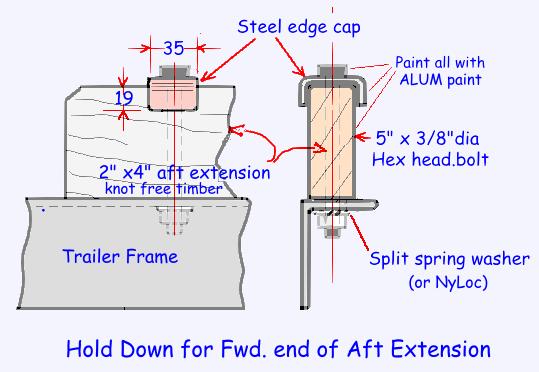

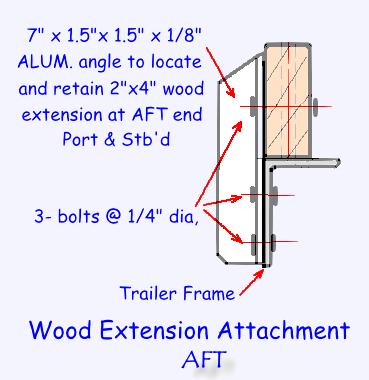

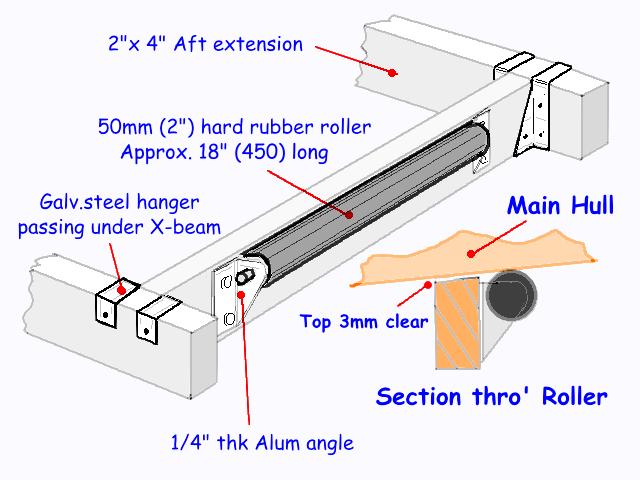

The rear extension is most easily done in 2”x 4” knot-free wood and this also gives a little more spring to the trailer to soften the shocks on the boat. Overlap this extension by about 4ft and here is how to attach it. The best way to lock down the forward end is to use a homemade 'steel edge cap' and single bolt (at least 4" from the end),

The rear extension is most easily done in 2”x 4” knot-free wood and this also gives a little more spring to the trailer to soften the shocks on the boat. Overlap this extension by about 4ft and here is how to attach it. The best way to lock down the forward end is to use a homemade 'steel edge cap' and single bolt (at least 4" from the end),  that will totally prevent the wood from splitting, and at the rear, it is bolted to short angle pieces that also bolt to the frame (see sketch at right) .. all very easy to do. Again, paint all non-alum work (steel or wood) with my favourite paint … 3 coats of aluminum paint .. the type that is heat resisting that also spreads a long way, penetrates, is water resistant, inexpensive and lightweight! What more can one ask for! It does takes time to dry though, so be patient or you will be covered in it. Every 3 seasons, I also recommend to lightly sand the surface and give another refresher coat … it’s well worth the small effort as the actual paint thickness is very little. It never peels, flakes or blisters though.

that will totally prevent the wood from splitting, and at the rear, it is bolted to short angle pieces that also bolt to the frame (see sketch at right) .. all very easy to do. Again, paint all non-alum work (steel or wood) with my favourite paint … 3 coats of aluminum paint .. the type that is heat resisting that also spreads a long way, penetrates, is water resistant, inexpensive and lightweight! What more can one ask for! It does takes time to dry though, so be patient or you will be covered in it. Every 3 seasons, I also recommend to lightly sand the surface and give another refresher coat … it’s well worth the small effort as the actual paint thickness is very little. It never peels, flakes or blisters though.

At the rear, add a solid rubber roller of at least 2”diameter (with alum brackets to suit). There are some already-made rollers for trailers but they can be expensive, so you may wish to search for an old wringer roller, or you can make your own roller with a heavy wall PVC pipe with 3/8” of rubber bonded around the outside. I suggest to cut the butt join for the rubber on a slight angle, so that the joint does not run straight across. I think it’s less likely to peel off like that … and use a bonding cement that is waterproof .. like epoxy, a  marine polyurethane, or high quality rubber cement. The end bearings can be ½” thick disks (bonded inside the tube) of fiberglass or carbon fiber, and use a steel pivot of at least 3/8”diameter (preferably stainless) that will be about 21” (530) long. I would not be too concerned about the tube flexing slightly in the middle as the boat weight once on the trailer, will mostly be at the outside edge where the disks will be, loaded by the very rigid vertical sides of the boat.

marine polyurethane, or high quality rubber cement. The end bearings can be ½” thick disks (bonded inside the tube) of fiberglass or carbon fiber, and use a steel pivot of at least 3/8”diameter (preferably stainless) that will be about 21” (530) long. I would not be too concerned about the tube flexing slightly in the middle as the boat weight once on the trailer, will mostly be at the outside edge where the disks will be, loaded by the very rigid vertical sides of the boat.

Trailer suspension IS an issue with these semi-elliptic springs as they are clearly not very compliant. I do have a much better ATL design (Adjustable Trailing Leaf) that I normally far prefer to use, but it does require a new mini-subframe that, at the time I prepared mine, there was no time for as I needed the trailer urgently to make a promised trip to a Boat Show. So here is the option most will use.

As the trailer is rated for 1170 lbs payload and we only need 500 lbs, I removed one (or was it 2?) of the spring leaves each side to soften the suspension a bit, leaving only the main long leaf plus one short one that distributes the axle load to the mainspring. Check out this pic above, taken with the trailer frame upside down and AFTER the unused spring leafs were removed. If you do the same, keep in mind that your trailer is now rated with a 500 lb max capacity when using it to haul other things. I strongly recommend to degrease and sand all steel parts before giving them 3 coats of aluminum paint and then re-assemble with grease under the curved end of the leaf that slides. Do this before assembling the trailer.

As the trailer is rated for 1170 lbs payload and we only need 500 lbs, I removed one (or was it 2?) of the spring leaves each side to soften the suspension a bit, leaving only the main long leaf plus one short one that distributes the axle load to the mainspring. Check out this pic above, taken with the trailer frame upside down and AFTER the unused spring leafs were removed. If you do the same, keep in mind that your trailer is now rated with a 500 lb max capacity when using it to haul other things. I strongly recommend to degrease and sand all steel parts before giving them 3 coats of aluminum paint and then re-assemble with grease under the curved end of the leaf that slides. Do this before assembling the trailer.

To receive and support the boat at the bow, you will first need a wood support of 2” x 8” laid flat and bolted across the top of the A-frame. Use only one 1/4” bolt each side as you want the minimum no. of holes in this alum frame. To this plank, screw & bond a ~16” x 3.5” x3.5” wood block at the center. Then add a 3/4“ plywood plate vertically over the front face and make two side supports that can pivot down as shown in the photo above left, using S/S wingnuts. The two side supports will be left UP most of the time,  but there will be times when you want to incline the main hull over about 60 degrees to do maintenance work on the bottom or DB slot … and for this you will need to lower those small side pieces up-front or you risk to pierce a hole in the side of your boat !! To prepare to incline a W17 like this, you first take off each ama by first unlacing the tramp and then pulling the upper hinge pins to lower the ama down. Then remove the under-latch bolts, when the ama is free to be moved away. (this is also the best way to repaint them when needed).

but there will be times when you want to incline the main hull over about 60 degrees to do maintenance work on the bottom or DB slot … and for this you will need to lower those small side pieces up-front or you risk to pierce a hole in the side of your boat !! To prepare to incline a W17 like this, you first take off each ama by first unlacing the tramp and then pulling the upper hinge pins to lower the ama down. Then remove the under-latch bolts, when the ama is free to be moved away. (this is also the best way to repaint them when needed).

You then incline the main hull until the central beam-ends almost touch the ground …, where you can put a 3/4“ wood (or dense foam) pad. It’s easier than it sounds and another very useful feature of the design. Easy under-hull access.

The final thing you will need is a light-bar at the rear. I prefer to not use trailer lights attached to the trailer as then they go in the water when launching and soon rust out and you'll soon have corroded connections. So I make a bar of a 2” x 4” timber with a hole through each end for ropes to lash it to the alum. trailer frame, laying the bar against the rear of the aft beam across the deck. The lights (and license plate) are attached to the 2 x 4 and have a long electrical line (4 wires) that reaches your tow vehicle with a couple of feet to spare .. with a plug-in connector.  So when launching, remove the light bar first and coil up the electric wire. Once the empty trailer is hauled out., you can attach the light-bar to the bare rear frame of the trailer using bungee cords and after plugging in, you’re all set for the road again.

So when launching, remove the light bar first and coil up the electric wire. Once the empty trailer is hauled out., you can attach the light-bar to the bare rear frame of the trailer using bungee cords and after plugging in, you’re all set for the road again.

It's also very useful to install a couple of slightly flexible (PVC conduit) guide posts at the rear, so that the boat arrives centralized on the trailer or more specifically on the roller ... which, as shown here, can also be made in two halves with a support in the center. Just be certain that the metal bracket tops are safely below the roller surface. The rollers shown here run on a 1/2" rod.

If I think of anything else, I will add it here later. Hope this helps.

OK…. A few words on hitch load. Particularly with the somewhat weaker aluminum trailer, a hitch load in the 40-80 lbs range works fine .. or 6-10% of the total trailer weight plus boat. The up-and-down load at the hitch (due to road dips) is typically about 5% of the total weight, so you want enough load on the hitch to keep this positive. While having more than 10% on the hitch maybe ok from the trailer-stability viewpoint, excessive load can take weight off the front steering wheels of the tow car and destabilize the whole rig, so personally, especially with a small car, I prefer to keep the hitchload in the 7-8% range. With such a fine range, it’s important to make adjustments if you are adding say a mast that may add more weight aft. This either means starting with the boat more forward, or you can temporarily add some weight in the bow of the boat.  On the 7.80m Magic Hempel, I used to plug the drain and add 4 galls of water in the anchor locker which was then easy to drain out when no longer needed but on the W17, one can store a couple of gallon containers of water up forward if needed. If the boat and trailer is too heavy on the front end to be able to handle the trailer once off the hitch, there are options. One can either use a trailer hitch dolly (home buildable in wood for loads under 150lbs) or temporally add a heavy, compact weight in the aft ‘sugar scoop’ of the W17. An old 60lb (27kg) battery works great for this.

On the 7.80m Magic Hempel, I used to plug the drain and add 4 galls of water in the anchor locker which was then easy to drain out when no longer needed but on the W17, one can store a couple of gallon containers of water up forward if needed. If the boat and trailer is too heavy on the front end to be able to handle the trailer once off the hitch, there are options. One can either use a trailer hitch dolly (home buildable in wood for loads under 150lbs) or temporally add a heavy, compact weight in the aft ‘sugar scoop’ of the W17. An old 60lb (27kg) battery works great for this.

As far as the tow car is concerned, even a small car with a 1600cc motor and 80hp, will pull a W17 just fine, but I suggest to limit speed to 60mph (100km/h) or braking may be too compromised. Drive safe and 'baby that boat' ;). In my experience, trailerable boats suffer more serious hull damage on their trailers than they ever do in the water!

Mike, March 2021

.

Feel free to send in specific questions or comments via my Questions Form, that I may select to answer through this website if considered of broad interest.

"See the Copyright Information & Legal Disclaimer page for copyright info and use of ANY part of this text or article"