SETTING up FORESAIL SHEETS on a W17 trimaran

.

QUESTION: How would you suggest to set up the various fore-sail sheets on the W17 ?

ANSWER: see text and images below: …. R.M . Oregon, USA

For the genoa, screecher, Code-0 etc. I recommend a single block (each side) strapped to the rear beam. The strapping (rope or webbing) allows its position to be readily adjusted in or out depending on wind angle. For the Spinnaker I suggest a block shackled to the aft shroud eye on the outer end of the aft beam (see photo), as this will be sheeted much farther out than for the genoa that will typically be quite far in. Once the sheets are reeved through these blocks, you can personally decide (after sailing tests) where you prefer to mount a cam-cleat so that you do not have to sit on it too often ;) Having ‘bent’ the sheet over 90 degrees at the block, this cleat will not take a very high load, but should still be screwed into at least 12mm of good wood or have a small 6mm plywood doubler under the seat or cockpit locker top.

For the genoa, screecher, Code-0 etc. I recommend a single block (each side) strapped to the rear beam. The strapping (rope or webbing) allows its position to be readily adjusted in or out depending on wind angle. For the Spinnaker I suggest a block shackled to the aft shroud eye on the outer end of the aft beam (see photo), as this will be sheeted much farther out than for the genoa that will typically be quite far in. Once the sheets are reeved through these blocks, you can personally decide (after sailing tests) where you prefer to mount a cam-cleat so that you do not have to sit on it too often ;) Having ‘bent’ the sheet over 90 degrees at the block, this cleat will not take a very high load, but should still be screwed into at least 12mm of good wood or have a small 6mm plywood doubler under the seat or cockpit locker top.

For the standard blade jib, I recommend mounting the round base of the fixed jib-sheet lead block on a roughly 5” (125) square of plywood x ½” thick, made by laminating two 6mm thick strips with the outer grain placed at 45 or 90 degrees, that are placed in the most forward cockpit locker access slot, with the upper and lower ends well hooked in. The block suggested is a Barton #02170, with a spring under the block to make it stand out from its mount and not fall down (which could jamb the sheet)..

For the standard blade jib, I recommend mounting the round base of the fixed jib-sheet lead block on a roughly 5” (125) square of plywood x ½” thick, made by laminating two 6mm thick strips with the outer grain placed at 45 or 90 degrees, that are placed in the most forward cockpit locker access slot, with the upper and lower ends well hooked in. The block suggested is a Barton #02170, with a spring under the block to make it stand out from its mount and not fall down (which could jamb the sheet)..

Initially, I suggest to hold the mount in location with a temporary spring or G-clamp until you decide its best location to suit your mast rake and sail shape. In my case, this was at the forward end of the forward opening.as shown in this photo. Once settled, add one screw through the face of the cockpit box to prevent it from sliding, but do not glue it. This way, you can still relocate it later if need be.

If the block mounting strip fits snugly between the locker bottom and the upper deck support, and your cockpit face ply is 6mm, you will not need additional strengthening. But if your plywood is under 6mm, then first bond in two 6” x 1” strips of 6oz FG boat cloth on the inside of the top and bottom of the cockpit-box side for the new pad to bear against.

The jib sheet needs to b e a 2:1 to make sheeting-in tightly an easier task. Start by tightly wrapping the free end and even tapering it slightly. Now feed it through a 3/8” dia hole drilled through the outer gunwale under the cockpit seat a suggested 510mm’s aft of the forward beam. (This position may vary with the cut of your jib and your mast rake). The dead end of these sheets should have a simple stopper-knot and a 3/8” S/S washer then slipped down the full length of rope, so that when pulled through the hole in the cockpit side, the washer lays against the outside of the gunwale, hidden under the seat overhang. The sheet is now fed through one of two blocks attached one each side to the clew cringle of the jib, and then back to the outstanding block mounted as above in the sloping cockpit side. (see photo), After that, the end will be cleated in a camcleat screwed either on the inner edge of the cockpit seat as shown, or in an optional cleat on the opposite cockpit box. This latter position is not essential but can be useful in gusty weather (especially if sailing alone from the trampoline), as that cleat is more accessible from the windward side. Personally though, I use the one shown in the photo above about 90% of the time.

e a 2:1 to make sheeting-in tightly an easier task. Start by tightly wrapping the free end and even tapering it slightly. Now feed it through a 3/8” dia hole drilled through the outer gunwale under the cockpit seat a suggested 510mm’s aft of the forward beam. (This position may vary with the cut of your jib and your mast rake). The dead end of these sheets should have a simple stopper-knot and a 3/8” S/S washer then slipped down the full length of rope, so that when pulled through the hole in the cockpit side, the washer lays against the outside of the gunwale, hidden under the seat overhang. The sheet is now fed through one of two blocks attached one each side to the clew cringle of the jib, and then back to the outstanding block mounted as above in the sloping cockpit side. (see photo), After that, the end will be cleated in a camcleat screwed either on the inner edge of the cockpit seat as shown, or in an optional cleat on the opposite cockpit box. This latter position is not essential but can be useful in gusty weather (especially if sailing alone from the trampoline), as that cleat is more accessible from the windward side. Personally though, I use the one shown in the photo above about 90% of the time.

Although the jib sheet typically follows the triangular pattern shown by the dotted line in the photo, there are occasions in light weather when you need less horizontal pull (to give more camber) but still need some leech tension to point well. For this case, I recommend to install a small nylon (or metal) hook (pointing down) about 330-350mm farther forward at the side of the cockpit seat, to hold down the fixed end of the sheet, to change the resulting sheeting angle (see photo).

The sheets need to be long enough to allow the sail to go fully to either side. This should then prove long enough to spin around the furled sail and still have a little spare at the cockpit-end to firmly tie to the mast tiller from each side, to stop it from rotating when the boat is moored or on a lift. This is to reduce mast wear at the pivot and shroud wear at the hounds.

One problem that can be annoying is that the double jib sheet can be pulled under the front-bottom of the mast and risk to be prematurely worn or damaged. To avoid this, I wrapped the bottom of the mast in kitchen plastic wrap and then moulded a couple of layers of 9oz glass over it to form a well-fitting collar. To the base of this, I shaped a piece of ½” plywood and moulded the bottom of the f-glass over it. Once cleaned up and smoothed over, it created a piece like this photo shows, that sits right down to barely 1 mm above the main beam and is held to the mast with just two self-tapping screws, as you probably want to remove this when you remove the mas t from the boat. It’s installed and just visible on the photo above showing the jibsheets.

t from the boat. It’s installed and just visible on the photo above showing the jibsheets.

.

.

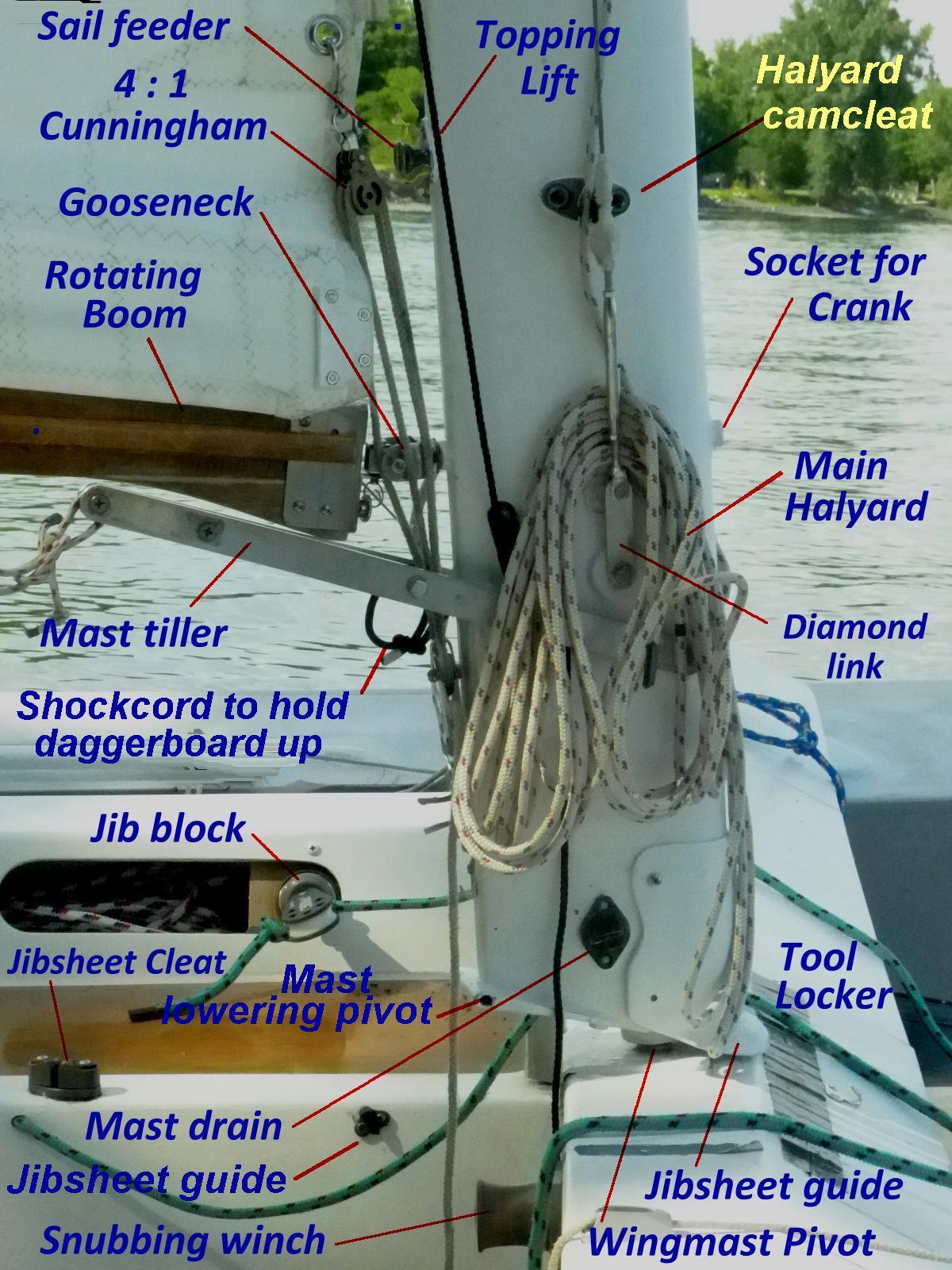

Finally, because it may be useful to some ….here is a shot at the foot of the wingmast of my boat ‘Magic’. It might look complicated but it’s really not, but I have marked up each item as to the purpose it serves. This pic has enough resolution to be enlarged if need be.

.

Hope this covers your needs ok ........

.

Mike… November 2021

.

"New articles, comments and references will be added periodically as new questions are answered and other info comes in relative to this subject, so you're invited to revisit and participate." —webmaster

"See the Copyright Information & Legal Disclaimer page for copyright info and use of ANY part of this text or article"