.

What are Mainsail End Plates ?

……… how do they work, and how might they be made ?

Vertical sails are

in many ways, similar to horizontal plane

wings …. where air of higher underside pressure escapes to the upper lower

pressure side at their ends, typically in a swirling inefficiency called a

Vortex. High pressure bleeds off to

the low pressure area, creating local drag and lowering flight efficiency ….

requiring a little more power to compensate, which of course means more fuel,

resulting in higher cost & less range.

To limit that on planes, we see more and more End Tips called

WINGLETS. By lowering this ‘bleeding

effect’ (near impossible to stop completely), the higher velocity / lower

pressure area above the

wingtip stays less disrupted, resulting in less drag … and some fuel is saved.

But unlike a plane wing, a vertical sail has end losses at both ends of the aerofoil - so at the

foot and at the peak, but as the issues and solutions are different, I

will just start with the lower one at the foot. With sailboats, it’s not the cost … it’s

drag and some loss of sail efficiency.

With soft sails that have less pressure differential side-to-side and general operate at slower speeds it’s not a HUGE effect, though with rigid wing sails and higher speeds, it typically will be. Just listen for 1 minute, (minute 23) on this YouTube to hear an experts view.

https://youtu.be/H_4Dbc4Pdnw?is=ZPS8E5iKtATuafPP

There, the sail trimmer (Paul) from the Canadian SailGP crew,

gives a fine detailed description of what’s involved to sail on of these

amazing machines. He firmly underlines

that IF the lower edge of the wingsail is not tightly sealed (to the deck in

this case) that the loss in power is HUGE.

But this is not the installation that general

sailboats can or will have. With a soft sail and lower air

speeds, the effect will be far less

but still worthwhile for anyone interested in racing or to just improve

efficiency, as I might ;) For regular

sailboats, there is almost no possibility of sealing the lower mainsail foot

tight to the deck or even to a coach-roof top, but the smaller we can make the

gap, the less loss we incur. Generally,

the best we can do is to seal the mainsail foot to the boom and many cruising

boats do that anyway using a bolt rope tube or track. But then, there is another ‘loss’ built in,

as now all camber at the base of the mainsail is removed. This is exactly where we NEED the most

camber. as the air speed is lower here than higher up. So the logical solution is to set a loose

foot mainsail, ideally with a full length batten that has been stiffened aft

but flexes forward, so that when end-loaded, it takes up the aerofoil shape we

need for the sail at the foot. This

will now create a fairly large opening between the sail and the boom. THIS is the space that we ideally need to

close with a Foot End Plate (FEP) .. . with a closure that can be tacked from side to side automatically.

To find the first well-known solution to this issue, we need to turn back the pages of time almost 100 years, to the magnificent J-Class boats that were being raced in 1930 .. more specifically to the “Enterprise”, although other J-Boat’s did copy the solution as it was successful in winning the America’s Cup that year. This was the original ‘V’ boom that was closed on top, not like the more recent creation that is open for storing a flaked sail.

It was at least 4ft

wide as two crew members could walk down it side-by-side …. hence the catchy

name, ‘Park Avenue’ boom. On these now

rare pics from my files, one can see the tracks across the width on which the

slides ran, and the adjustable stoppers each side to control and define the

camber shape of the mainsail foot.

Because these boats sailed very close to the wind (and also did not race

in very low wind having a race time limit),the actual camber available

was really not great, so even with that width, the max camber was only about

1:30. By comparison, the FEP

developed for my boat “Magic” can show a camber of 1:10 which is way more effective in very low wind

conditions.

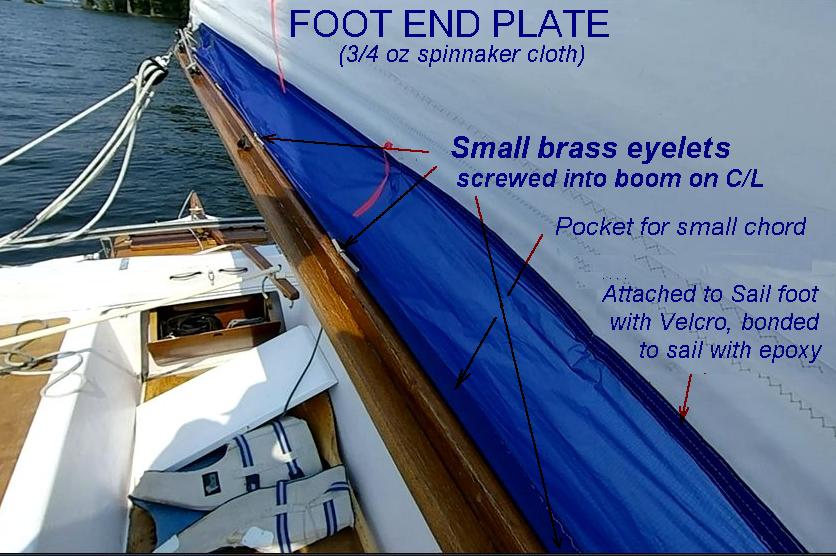

So here is what I am suggesting. A piece of light spinnaker sail cloth between the boom center and the foot of the loose sail. This can easily be arranged to tack automatically and mine stays permanently on my boom all season, with a simple, fairly air-tight link to the sail via a 15-20 mm velcro tape. It is super light, being of ¾ oz spinnaker cloth and only cost about US$15 (2023)

These pics will show all that’s needed to make your own. (I will add dimensions for the W17 FEP down

below). My centerline ‘hinge’ is

simply a tight 2-3mm braided cord passing through small brass eyelets where the

cloth is cut out. By spacing these

cut-outs about 500mm apart, one can still pass your fingers under the FEP

to grab the boom if so needed. You will be surprised to see how the

downward scooping air that would normally flow down under, ‘inflates’ this

cloth trap and visibly shows it’s working.

Of course, the actual added drive is really very small down this low, as

the air is always very disturbed by the cockpit and crew presence. But it’s a step in the right direction, when

‘every small thing counts’.

Now to the Peak End

Plate

At the upper part of the sail, the air speed and pressure is visibly much stronger (judging by sail tell-tails that are always worth adding).

But the chord is also much shorter (more like a plane’s

Winglet) so that moderates the effect, compared say, to the foot of a rigid

wingsail tight to the deck on a Sail GP, not to mention the enormous speed

difference that amplifies the effect.

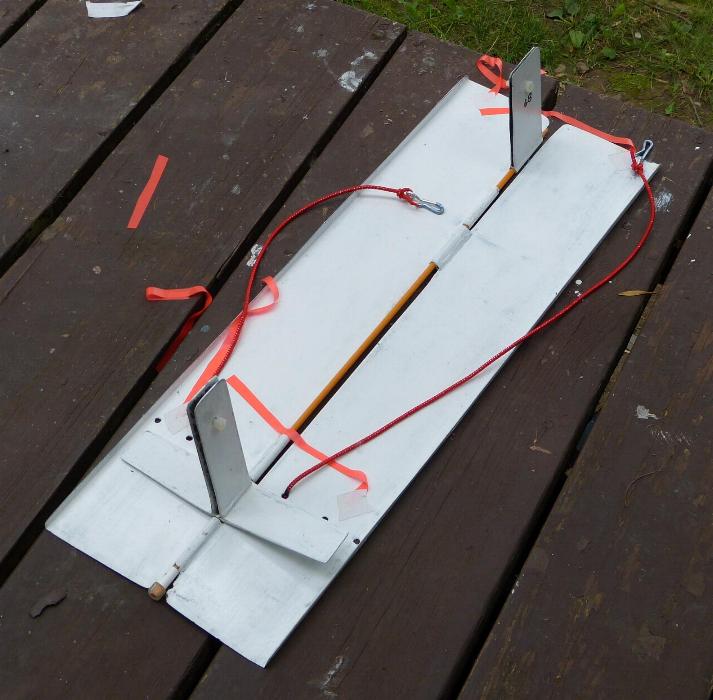

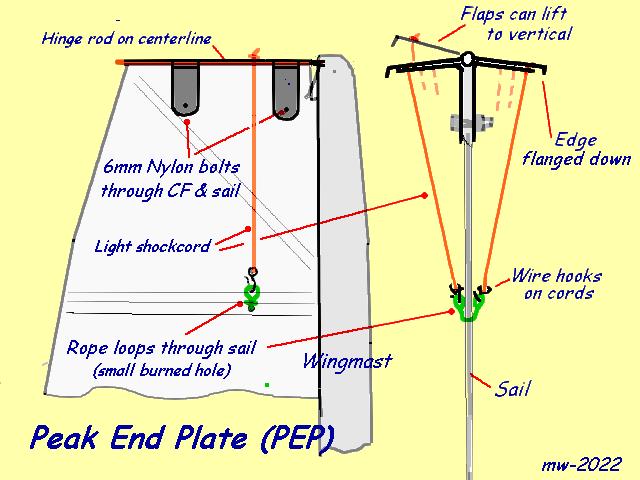

So this upper peak end plate (PEP) is far more like a Winglet, but it’s on both sides. As it will be high up and only reachable when lowered, we need it to not only function automatically but also be designed so that when a large gusts blasts up the sail, this high pressure is not trapped up there, adding to the risk of a capsize.

So the side Winglets or FLAPS as I call them, are very lightly retained by flexible shock-cords so that in a calculated situation (I use about 2lbs per sqft of flap area), the flap on the windward side will start to lift up, eventually parallel with the sail to relieve the pressure. With the right length, diameter and easy extension of shock-cord, this works very well. A very lightweight frame of carbon fiber was created that is held to the top of the sail with just two nylon bolts through the sail, and this frame supports the flaps from dropping down more than 85 deg to the plane of the sail .. which will be their normal operating position. Here are pictures of the parts and the installed PEP. The flaps are hinged to the ‘T’ shaped units using a fiberglass rod from a bicycle flag with the ends wrapped with tape to not slide out inadvertently.

The only problem detected in use, was that when the sail is

being hoisted or lowered, the topping lift must be held away from the mast for

its upper 25% (2m on a W17), or it can slide down into the hinge and jamb

things up. Below the 25% point, all is

clear, and there was no other issue encountered. It takes less than 10 mins to mount or

remove, so it may interest some.

The apparent wind in way of this PEP is clearly augmented, as

all the tell-taless fly aggressively rearwards with zero air seemingly passing

over the top of the sail. The overall

gain maybe in the 0.1-0.5k range, but in tight competition that’s all it takes

if rules allow such a device. It was not

banned in 1930 so why now ? Have fun

sailing with ‘peak efficiency’;)

Mike Waters …. Dec 2025

New articles, comments and references will be added periodically as new questions are answered and other info comes in relative to this subject, so you're invited to revisit and participate." —webmaster

"See the Copyright Information & Legal Disclaimer page for copyright info and use of ANY part of this text or article"