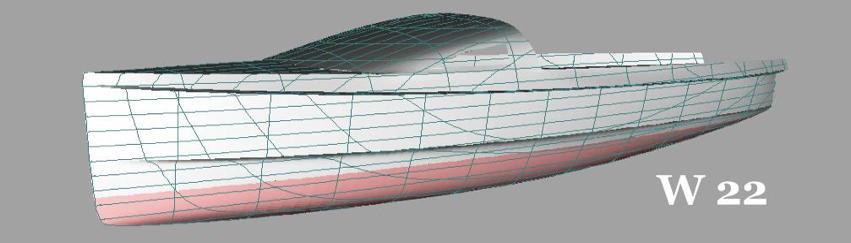

Design Characteristics of the new W22

As written in 2010 - check later for final decisions

The W22 is being designed as 'a better solution' for a boat that is relatively inexpensive and easy to construct, yet with fine performance and versatility. It also aims to be the 'driest fast boat' of its size and adaptable to individual owner's needs.

Main Hull

The main hull will be as slim as practical both at and below the waterline and that will depend on keeping the overall weight down as much as possible without resorting to extensive use of carbon that is expensive or light foams that really require vacuum‑bagging for an effective sandwich. Although the weight savings might look attractive, these foam cores are still about 3 times the cost of plywood and also require more glass for equivalent strength.

The W22 will have a significant flare above the waterline to keep waves and spray down as well as provide more space higher up. The hull will have near semi-circular sections to give the lowest wetted surface and buttock lines will be swept up less than most other designs, combined with a moderately fine entry.

Amas

I think the ama's role as a sailing hull has sometimes been overlooked, with the result that it's often designed more for just added stability rather than a hull that shares the total sailing load with the main hull. For that reason, the W22 will have an ama that will immerse its bow early and give good waterline length. This will also help the diagonal stability. Its center of buoyancy will be well forward, with a gradually tapered stern that will not lift the stern too much on heeling. This in turn, will help to keep the bow up. Initial plans are to get enough buoyancy into each ama to give well over 100% when the boat is light, yet not be excessive when the boat is fully loaded to keep beam loads reasonable and give a visual indication of when to back off. To sail efficiently when light, each ama will be fitted with a rudder to maintain steerage under all heel conditions.

Construction Materials

The hull will be a composite of several different materials, using the best one where it best fits, to give the most economical solution in both cost and building hours, for general toughness combined with reasonably low weight. This approach will also give the builder a chance to learn a little about each material as his/her skill progresses, without feeling overwhelmed by some new technology that might otherwise seem beyond them.

The underwater shape will not be compromised by this approach and there will be at least two options. The main hull will be build in two stages. First a semi-circular sectioned solepiece with a significant flare to deflect spray and waves just above the loaded waterline as well as provide more space. The flat topsides will be simply finished with marine plywood and that will readily allow the deck and cuddy to be easily integrated in wood. The exterior will be sheathed with painted glass and epoxy, for long term protection.

Initially, this lower solepiece will be homebuilt using cedar strips with a substantial glass covering and a kevlar keel strip. At least three bulkheads will be built in plus a vertical center girder, so with the added horizontal stiffness provided by the flare, this solepiece will firmly control the shape of the final hull. The horizontal cockpit and cuddy floor will add further to this.

The Amas, while always maintaining the same designed shape, will have several options for construction, including strip cedar, KSS or cylinder molding.

Filaments in Use

Although the exterior sheathing will be a 6oz glass cloth, there will also be places to use some roving, carbon fiber and kevlar. The idea is to let these materials do what they do best, but in small critical areas, rather than impose high costs for extensive usage. For example, lengths of carbon fiber will likely be specified around the ama sockets for the cross beams where there is high stress, as well as being used to spread loads from the ama side shell where the outer shrouds are attached. In a similar philosophy, the keel with have an exterior kevlar strip, as this material is great against abrasion.

Cross Beam

Ideally, I am looking for the beams to be of a mast section of about 5.5" × 3.5" that will provide enough side surface to walk on without its total length being too heavy or costly. As only 18 ft will be required for each beam and the aft one also of smaller section, pieces of previously damaged masts could well be used for this. This would be for the preferred demountable version. This design will be considerably less expensive to build than the F22 by Farrier, in large part due to his expensive folding system. Incidentally, the use of a 'pan' for the underwater hull, is not new. I personally drew up my first cat with this system in 1958 and Don Karmin had boats (Cobra Cats) in production with a similar 'shoe', in the early 60s). Mike Leneman's L7 also used them.

The demountable beams will have waterstays to support the crossbeams, which gives the lightest support system available. The waterstays can be flat stainless steel strapping or SWR with J-hooks. Either way, these will be designed and located to not create much water resistance or unwanted spray and be quick to attach. Generally similar to those on my last boat, Magic Hempel.

Arrangement

In the interest of being versatile for most needs, the main hull will have a large 7' long cockpit with comfortable seating. Forward of that will be a low cuddy for short-period shelter and yet also have 7 feet of uninterrupted floor space for throwing down a sleeping bag for the occasional overnight for two. My experience has been that boats of this size and performance are used mostly as day sailors and too often, comfortable cockpit space is sacrificed in order to get more cabin space that is then used far less often. In this case, it will be the reverse. An excellent cockpit with comfortable sloping backs in both athwartship and longitudinal direction and a long, wide horizontal coaming to also sit on, but cut low enough to make moving out to the amas an easy task. A tent is planned to fully enclose the cockpit for overnight use—even in the rain—and the cuddy area can be closed with soft screens against pesky mosquitoes. The foredeck would be kept fairly flat and spread wider than the main hull topsides to provide a good working area to safely handle sails and the anchor. The latter would not require to be very heavy, so a small Bruce or Claw could be stowed in a dedicated pocket, forward of a collision bulkhead.

Trampolines

Contrary to many other boats, the trampolines will be positioned fairly low and run out flush to the deck of the ama. I have found this to be the most comfortable and more important, allows one to enjoy sitting on the ama to sail, without having one's feet too high up. I am also looking into some light molded seats with folding backs to be fitted at a couple of places, so that comfort is assured in all locations. My mantra of 'dry, comfortable and sweet handling' has come from spending 16 years with Magic Hempel the original Dragonfly, something that this boat was able to accomplish that many other fast boats have not. Click here to read more about Magic Hempel.

Mast

The mast will be of moderate height—enough but not extreme. Ideally a wingmast of carbon-fiber but not too tall to make that 100% essential, as a used alloy mast may be more economical. My CF Wingmast Mk l design does however enable the builder to create a more aerodynamically-efficient wingmast at a small fraction of the market price of a Pro CF mast though. (12% in 2012).

The wingmast will of course be rotating, with a single spreader and with 3 basic wires to keep it up.

In addition, there will be two temporary shrouds to the main hull to stabilize the mast while raising and lowering, something that can be possible while either on the trailer or not, so that low bridges can be passed under while on a trip.

UPDATE: Nov 2013

Mike Waters has been studying and evaluating various wingmast designs since 2007 and now offers one of his own with both his W17 and W22.

Sails

Sails will ideally be made to dimensions on the plan. In such a case, they will likely be of dacron. Before anyone jumps and screams, let me say that not only is dacron less expensive than more exotic alternatives, but will almost definitely be easier to handle and last longer. Even performance in light airs will likely be better and with full length battens, its performance in heavier airs will not drop enough to offset the other noted advantages in my opinion. Those who wish to race only and want the ultimate top end, will just have to accept to exceed the target cost and I hope they will be happy. Newer hi-tech materials have less stretch and less surface friction. But they are not so adjustable for light airs and have a shorter life span. Sailmakers like that of course, so buy smart.

Centerboard - Daggerboard

The final choice is leaning to a pivoting centerboard so long as I can satisfactorily solve the slot issue with a practical seal that will at least last a few seasons. Dagger boards ARE more efficient but that's mostly due to their snug slot and low resistance at the hull interface, but they are a liability in shallow, rocky areas.

Their longer length can help in some conditions, though I personally find this less of a factor with slim, low windage multihulls than monohulls or high windage multihulls, that really need more directional grip against drift.

Either way, the board will be stiff and only heavy enough to overcome its buoyancy, with a modern aerofoil section. There will be only one and that, in the centerhull. Two dagger boards (one in each ama) would only be justified to me on a super-light all-graphite boat that regularly flies the main hull. For the W22 they would be a pain as they would need constant adjustment with many trips out onto a wet ama that could otherwise be avoided.

Rudders

As noted earlier, I am planning on two rudders—one on each ama. Part of the reason is that such rudders may already be available from a suitable day catamaran and that would save a lot of work and expense. While  a central rudder on the main hull is easy to adjust and does not require a long tiller bar as would two rudders, there is the risk when sailing light, that the main hull will lift enough to allow air to the blade and therefore cavitate.

a central rudder on the main hull is easy to adjust and does not require a long tiller bar as would two rudders, there is the risk when sailing light, that the main hull will lift enough to allow air to the blade and therefore cavitate.

(That would happen on occasion on Magic Hempel—though she still sailed straight). Fitting a rudder fence against air traveling down, does help (see photo), but having a rudder on the pressed ama could be more secure.

Having two rudders even partly up, would still give adequate steerage in shallow water, while leaving from or arriving at a beach or shore.

The other advantage of two rudders, is that the main hull access over the stern for the motor or swim platform, is much improved and I like that.

Bowsprit

I like the idea of a rolled drifter/screacher as well as an asymmetrical spinnaker for improving performance off the wind, so a sprit would also be a must. Although an alloy tube can do the job, it would probably need bracing lines back to the amas and these get in the way when anchoring.

So I lean towards a section that is strong athwartship that would only need a vertical stay down to an eye at the waterline. I am considering a flat lamination or rectangular tube that would offer great side stiffness as well as a surface to place a foot on when one needs to be there for fending off or servicing a sail.

"Have a question or comment about the W22? If so, feel free to use our Questions & Comments Form to submit them to the designer." —webmaster

"See the Copyright Information & Legal Disclaimer page for copyright info and use of ANY part of this text or article"