The Price of Plans (2012)

Question: Why does the price of plans vary so much…and what might this mean to the design itself ?

Answer: Good questions. Plans for small trimarans are presently available from $150 to $1,500 a set, so that's a huge spread.

Well at the low end, there's NO one who can turn out plans and sell them for $150–$250 without either gambling there's a large market waiting for them OR having already sold enough copies in earlier years to cover expenses, that they are content to make a few $$ over the cost of printing new ones from the same old master drawings. And today, with all the design options out there, there's virtually no one gambling on big sales either. (Well, not quite no one … back later on this.) So cheaper plans are generally for older designs and only a very few of the older multihull designs still justify all the hours required to build them.

At the other end of the scale, there are designers like Farrier, Bisol and Kendrick, who have very detailed drawings for their masterpieces and therefore ask $1200 a set or higher. Even then, they will still need to sell quite a few copies to recoup their expense. Such detailed plans could certainly take 600 hours to complete (or I suspect even more for a Farrier) and even at $50/hour, that's still $30K! So at $1000 net per copy, they'd still need to sell at least 30 copies to break even. One of the few designers to make money at this has to be the honorable 'Sir Ian' and he's now (Ed: was) in an enviable position—as there are very few designers who have the luxury to take 2-3 years to draw up detail plans and STILL have clients who have waited (not always patiently) for plans to become available, without turning elsewhere for a design. But I have to admit, Ian's plans are/were quite incredible—every detail is spelled out both in 3D drawings and extended text. Even to myself who once worked as a senior draftsman they are intimidating in their detail, as all the small jobs that you the builder will one day have to face, are now staring at you all at once. So be prepared, it can be very overwhelming.

Many other good designers are forced to work a different way and that is to turn out less complex drawings at lower cost and then give phone support to fill in the gaps for those who are not able to work things out themselves. In fact, a large number of boat builders are NOT first-time builders and not only are they not particularly concerned about a few missing details but in fact, seem to go out-of-their-way to change the details that ARE given and end up creating 'a mongrel or hybrid' design, depending on how you look at it. Trying to do this with a design that has been deeply studied and drafted is a risky affair and one risks to find out much later in the construction just WHY 'such and such a thing' was done that particular way and the discovery is not always good news.

But designers who have not first created the network of 'fan support' that Ian did, can end up with some big bills to pay if they create super-detailed drawings without first being assured that the market it really there for their design, and those who have gone this route are out there to tell their story, as some have to me.

There is no doubt that some builders were pretty frustrated how Ian could hold his clients and builder almost to ransom over both plans and their need for his folding system—but you have to hand it to Ian—this did not happen overnight and he had the foresight to not only stay with a plan but also see that all parts of it—like website support, forum involvement, racing results, newsletters, marketing etc etc are kept going so that there IS in the end, the patience to wait for the full details of the next boat that he's promised to produce. Although one might on occasion take issue with some of Ian's design choices or compromises, I personally have the utmost respect for his 'work plan' and way he has made it work, year after year. [In Europe it's somewhat a different story. Countries are geographically close and sailors get to visually see and touch what is sailing around, rather than only getting the internet hype. That's why the Quornings' at Dragonfly Boats in Denmark, continue to do so well and generally outsell (and often outsail) the Farrier boats in Europe.]

But if you want to stray away from the Farrier family of designs and build something equally performing and perhaps even more satisfying, then you may have to accept to build from less detailed plans and also get to know your designer somewhat more intimately. It's not such a bad alternative. Just make sure the plan quality is there, so that you can clearly see and understand what you need to build.

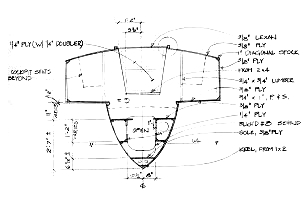

The designer will typically email you a custom sketch to solve YOUR specific problem or question and you may not even have to pay for it if the designer accepts that it's something you really needed to know. And for those who DO know how to build a boat and do not need every small millimeter of surface defined, then they'll not be bogged down into a myriad of details on multiple sheets of paper that they had to pay a high price for, when not everyone really needs it. Years ago, before the days of CAD, drawings were made by hand and as long as they contained a general layout, a section showing the size (scantlings) of main structural members and a table of offsets for the hull templates—then the boat could be built. Sure the details would vary, but the boats would work and the builder was proud of his achievement.

Today, the broad use of CAD has changed this a lot. But it's important to realize that while a computer can readily create fancy 3-D images, it's not the computer that designs a boat and just because the drawings LOOK real neat, that's no assurance that the boat will be any better than one built from old pencil drawings. Personally, I'd feel less stressed working from more basic global-outline plans with something left for me to figure out. However, some really appreciate all the detail and from what I've seen, Ian's multiple books of details and written procedures are the ultimate instructions for those who need that level of instruction.

So can you work with this?

Or do you need this?

Or how about this?

Or do you need this?

The way I see it they can all work, as long as the designer has updated the plans after a prototype has been built. Working with great detail or not, either way you'll probably spend about the same amount of time—either pouring over all the details to understand them—or the same time, with paper and pencil, figuring out how to solve a little problem that was either not foreseen or undefined on the initially simpler-to-understand plans, from someone who charged you less. Just as some enjoy building as much or even more than they enjoy sailing, some builders also like to feel they have been part of the design process by working out their own details. Both work—but for different‑minded people.

A compromise might be to budget for say $500 for slightly less detailed plans. At 1–2% of the potential value of a finely constructed boat, that's surely a real bargain.

Either way, get out there, chose a good design for a boat that really fits your needs AND that you'll be happy with for at least 5 years—and then start building! And prior to that choice, at least organize to sail a boat of the same general style and type, and only buy the construction plans a few months before you plan to start, but then commit. We do have such a strange tendency to change out minds ;-)

"New articles, comments and references will be added periodically as new questions are answered and other info comes in relative to this subject, so you're invited to revisit and participate." —webmaster

"See the Copyright Information & Legal Disclaimer page for copyright info and use of ANY part of this text or article"